dculberson wrote:Yay updates! Are you going to put any sort of ventilation in the paint booth? I am interested in doing the same thing in my garage some day and want to contemplate the fresh air angle.

We've got a couple of big 220V squirrel cage fans out of industrial air handlers that we're gonna rig up with some creative ducting to create a forced downdraft. The creative part comes in restricting the flow so we're not moving so much air it affects the paint spray...hopefully it works, because if we're successful we're gonna redo my Ramcharger, then put a new bedside on Mike's Duramax Chevy, and my brother in law wants to repaint the bed on his Dakota.

Alex, this Energy Suspension kit didn't come with any grease, but Mike is an Amsoil dealer so we've got multiple tubes of their super heavy duty grease (it's made for lubing the hitch plate on tractor-trailers) and I think it'll work just fine in this application. We're definitely gonna grease the hell out of every single point we can think of.

Pete, I'm still torn on the final coating for the brackets and such. If I can figure out a good way to suspend them and access all the sides I may go ahead and shoot them with the same industrial enamel I'm using on the frame.

Today we got the paint and set about thoroughly cleaning the HF paint gun. Numerous sites said that a thorough cleaning before use is imperative with this gun, so that's what I did. Once that was taken care of we set about mixing up the paint.

Now, you'd think, based on the first pic here, that pouring this 16oz can into 128oz of paint (or 1:8 or 2:16, since the sprayer hopper is 20oz) would sufficiently reduce it so that it could be pneumatically sprayed - afterall, it says right there on the got-damn can "add one pint to a gallon for the perfect spray." Well, it turns out that this is NOT actually the case. My first attempts were butt turrible to say the least. Ever seen the spray coming out of a ceiling texturing gun? Imagine that, only black, and that's basically what I was laying down. Then Mike has the brilliant idea to cut it some more with some mineral spirits. So we add 4oz to the 19oz we had already (16 paint + 2 reducer + 1 hardener) and that thins it out enough to spray a little better. Getting annoyed at the wind's constantly-shifting direction and increasing chance of blowing the overspray back in my face, I continue spraying, while Mike mixes up the next batch with the rest of the spirits we have on hand, and as I empty the hopper we refill with this new batch, which is thinned about 1:2. This sprays acceptably, since it's just the frame, but I'm still not impressed. At this point, having run out of spirits (also Mike determined somehow that the reducer we bought is actually not the proper stuff for this paint, so we stopped using it) I finished up what I had left and cleaned the gun. Mike ran out to Autozone for another can of spirits so I could properly clean up (it's the closest store that had any in stock, and I started cleanup with the nasty used stuff I had cleaned the gun with initially) and came to the conclusion while reading the back of this can - which is Rustoleum brand and sold right next to the gallon cans of their enamel paint - that we should have been cutting the paint 1:1 all along. When we flip the frame for access to the underside we'll try that and see what happens, but for now, it's good enough. If the other side turns out better I'll take the sander to the rest of the thing and scuff it up and shoot it again.

We also got a proper second test of our home-brew moisture separator, which is the big copper apparatus standing up by the air compressor. It's a 10' stick of 1/2" copper, cut into two pieces 4'10" long, and connected together with the remaining 4" of copper and some 90s, and soldered together. There are NPT adapters on the bottom with drain petcocks in both sides, and the air inlets are soldered into a T about a foot off the bottom. The length of copper forces the air to condense and, believe it or not, it actually works PRETTY DAMN WELL. Amazingly, for sure. We've gotta mount it to the wall at some point, but right now, who cares, it's out of the way and it's not going anywhere.

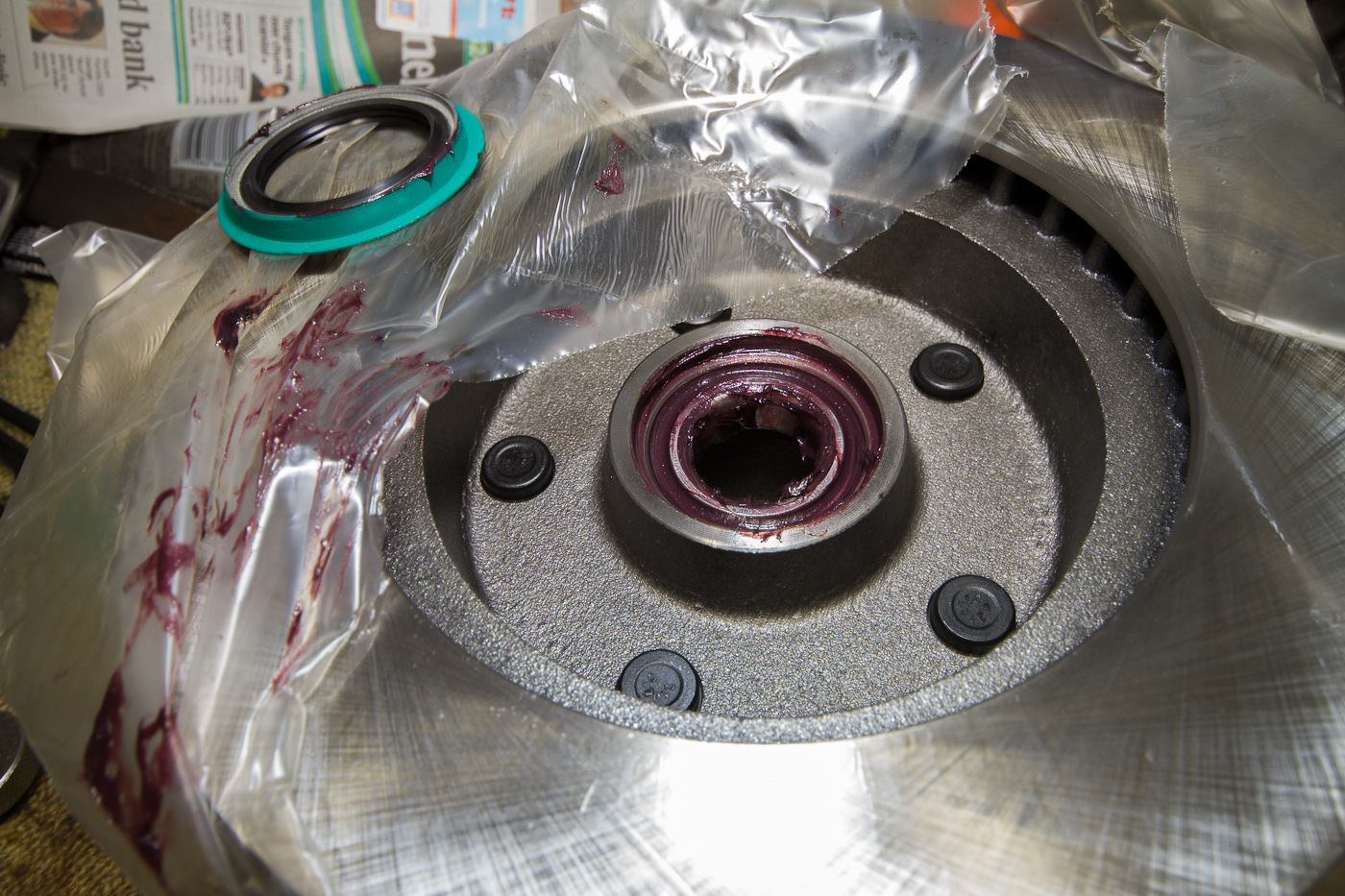

Mr. UPS man delivered our first-round Rockauto clearance haul (thanks Brett85p!!!) consisting of brake hoses, upper and lower ball joints, radiator cap, thermostat, coolant temp sender, and power steering pump rebuild kit - a whopping $30 worth of parts.

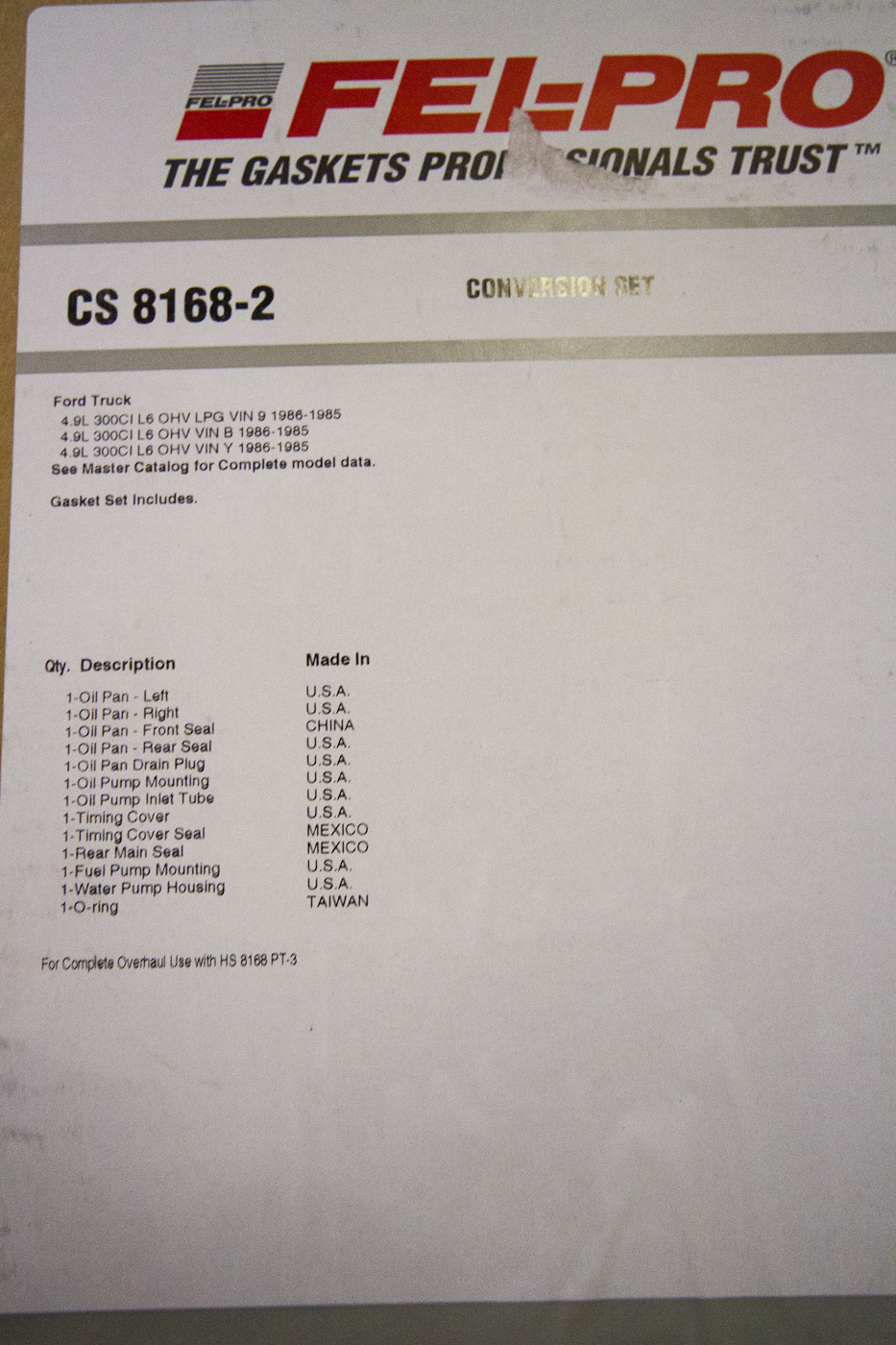

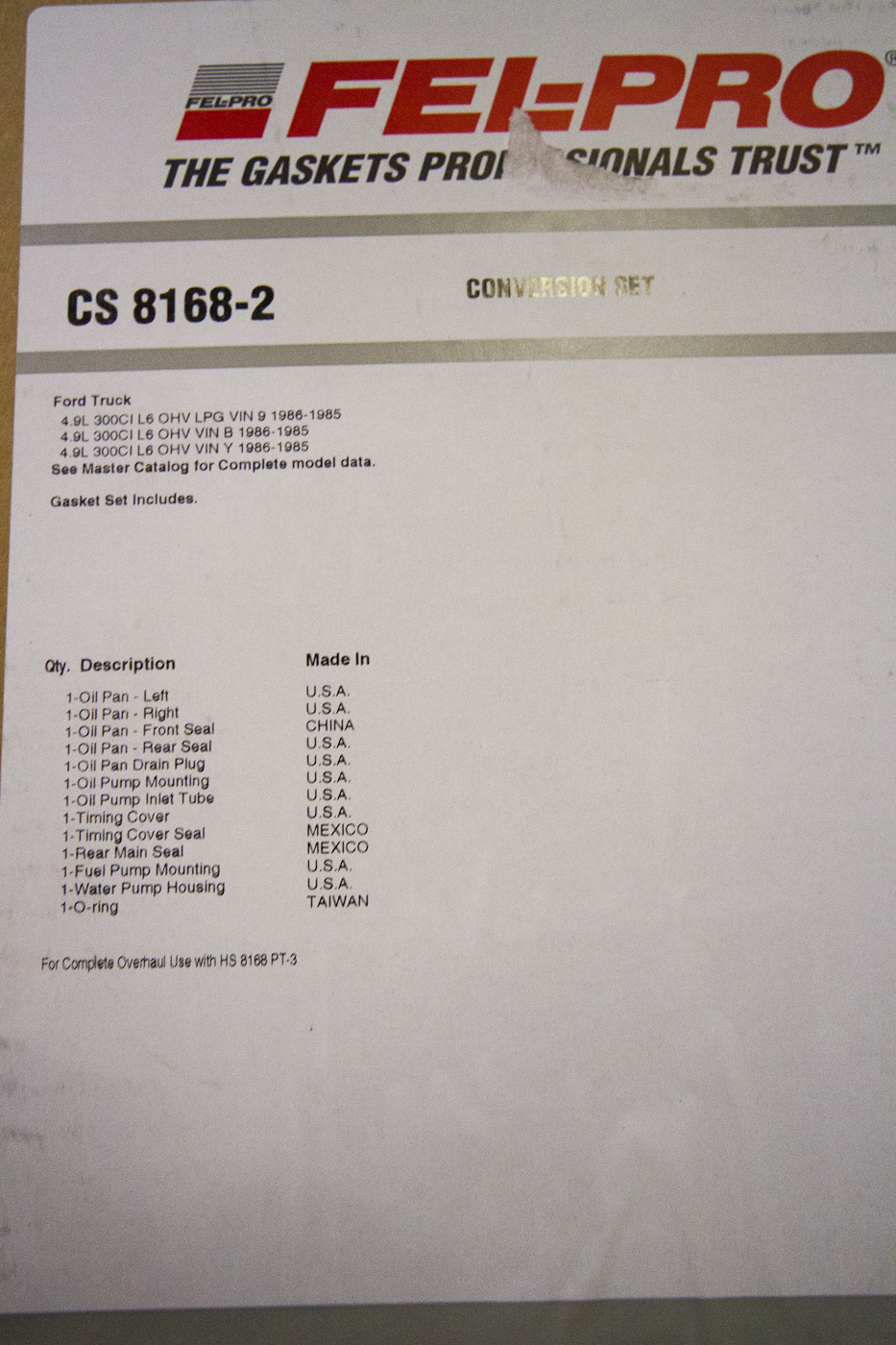

Autozone also managed to get the gasket set in a day early, so that was good. Also the water pump and oil pressure sender.

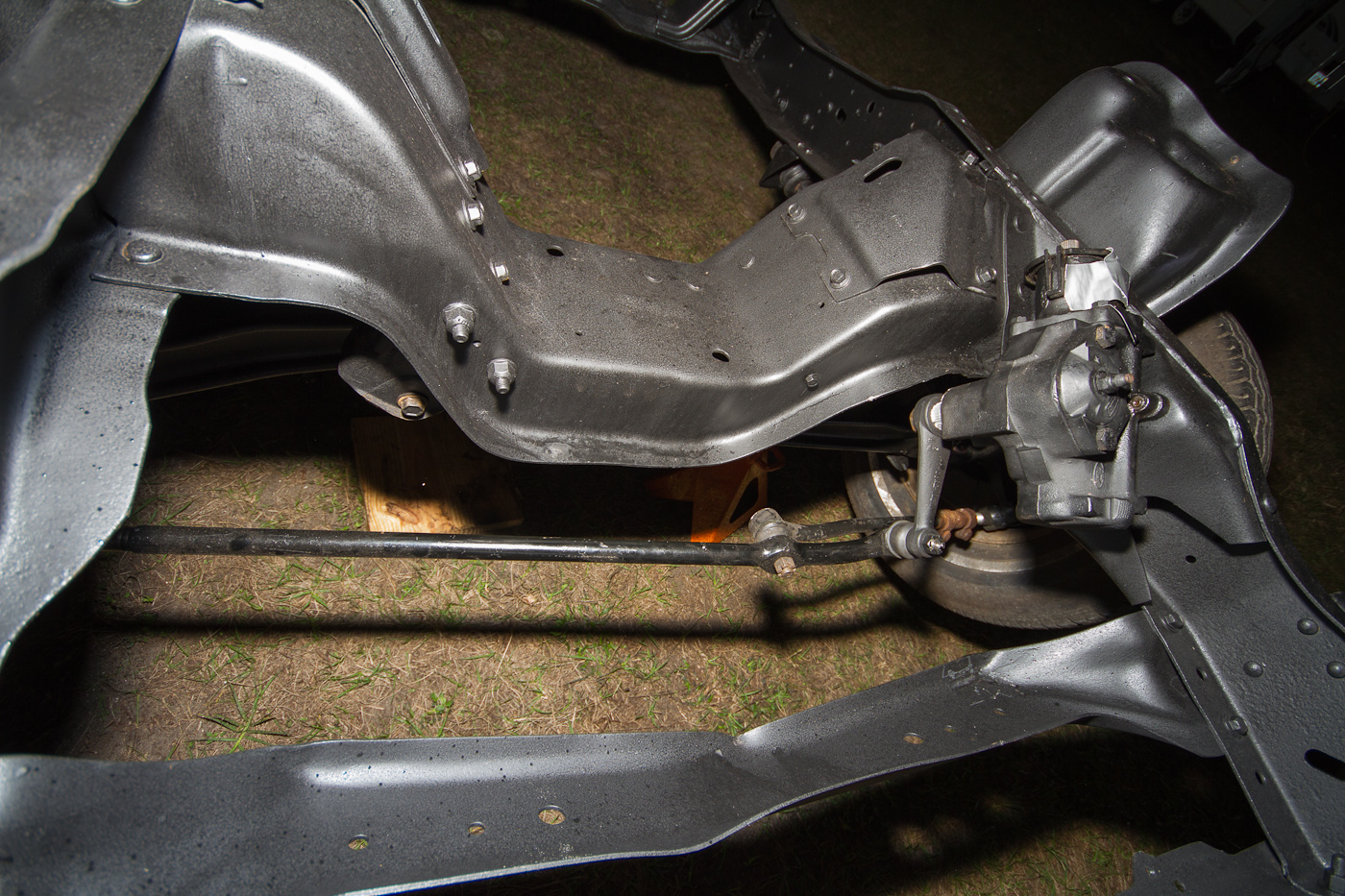

Bushings arrived last week, but I never took a pic of them. Turns out the kit Summit sold us is actually for a 4x4, but pretty much everything will fit anyway, and what doesn't (leaf bushings, which are the right diameter but too long) will with a little persuasion from Mr. Sawzall.

So, yeah, back to the frame. You can see a lovely run in the 2nd rear crossmember, due to poor technique on my part. Fortunately it'll have a bed sitting above it, so this is the only time anybody will actually see it, and hey, extra paint = extra corrosion protection! Right? RIGHT.

This is only about a half hour after the final bit of spraying, so it's not dry yet, but you can see some serious orange peel in it. Hopefully it dries a little flatter, we'll see Thursday, after it's had a two full days to bake in the Florida sun...

Coils are gonna need some attention with a brush, but I'm OK with that. I didn't disassemble the leafs fully (Mike vetoed that plan) so they're cleaned up as good as we could get them and they got sprayed too. They still need some attention to detail with the brush, as well...

"greasy side" of the frame, as in "keep the shiny side up and the greasy side down." There better not be any fucking grease on this any time soon!

Drums are toast, as are the tires, so who cares about overspray here. It needs a second coat of paint.

Gas tank hasn't really been cleaned up. The whole bottom half of it (below the seam) is still NASTY, with a healthy coating of grease and dirt. It's gotta be pressure-washed, and I've gotta pull the sending unit out so I have a nice big hole to stick the pressure washer wand into to blow out some of the varnish that's in there. After that I'll probably drop some rocks and some kind of strong solvent in there, and give it a vigorous shake to try to clean it up some before putting it back together and getting it ready for paint.

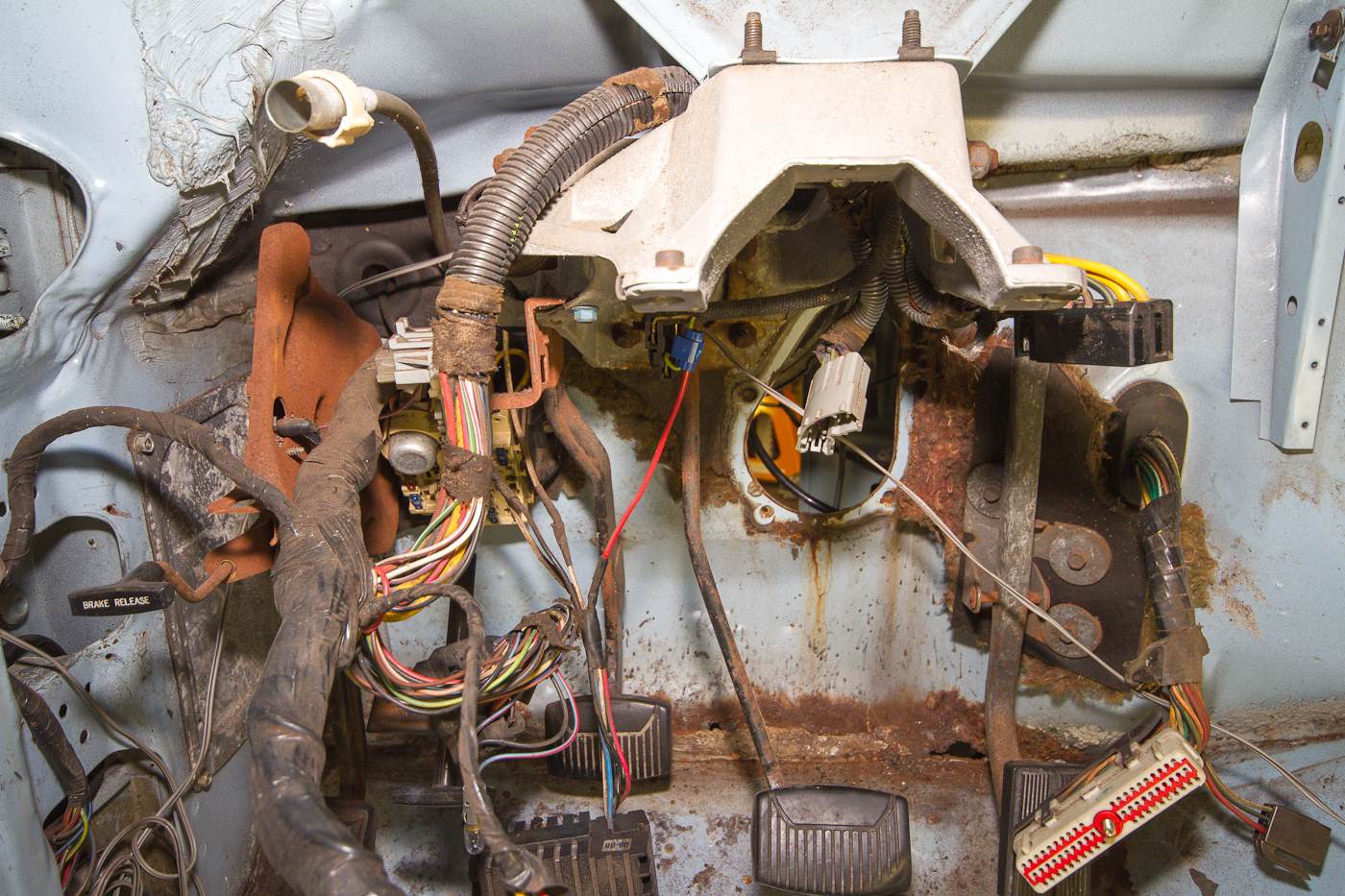

So, Thursday we'll lift the frame with the loader and flip it over so that the rail that's facing the ground can be painted. If all goes well with the "new" paint plan, we'll flip it over Friday and do the side I did today once more. If not, whatever, it's still lightyears ahead of where it was. Gas tank has to be addressed, and the rear needs a second coat. Either Saturday evening or next Monday (Mike has family in town this weekend, so Sunday is off-limits) we'll either lay the frame down and start putting the suspension back together under the lights, or work on the motor. Current plan is to hopefully get the motor and trans in the frame within the next week, and perform an ops test before the body gets done.

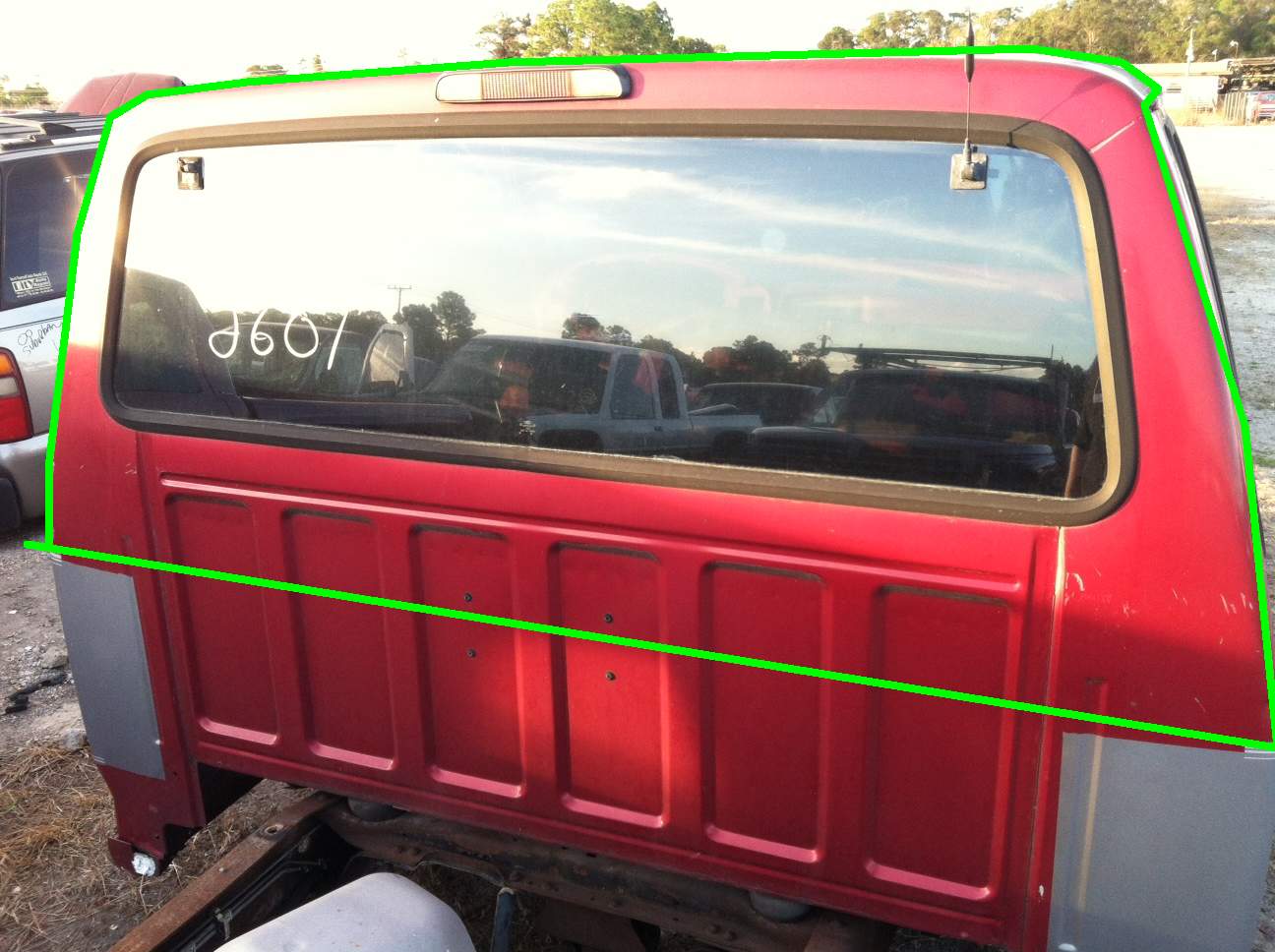

And on the subject of the body, I was talking to Jeff (Speedycop, duh) on the phone earlier this evening and he said that instead of buying a sheetmetal brake and trying to fab patch panels for the rear window frame, why not just take my handy DeWalt 18V sawzall to the junkyard and cut a frame out of a truck with less rust. This is a BRILLIANT plan and when I told Mike a half hour later he had the same sort of epiphany I did. He's gonna start calling junkyards (there are LOTS of them around here) tomorrow morning when he gets home from Alro with a 4x8 sheet of 20ga and (hopefully) a 6' stick of 4" c-channel so we can make a new crossbar for my press, and if he finds anything I'll go to the yard Monday or Tuesday when I'm off work again. Oh, also today he got a regulator for our MIG and a bottle of CO2/argon welding gas, which will come in handy once we get the new window frame bits to weld in.

Official photographer/Team Police Brutality|Speedycop & the Gang

Lackey-mechanic-whatever/NSF Racing

Sycophant/Judge Phil, Jay Lamm, Kim Harmon

Galaxie Driver/not Parnelli Jones