Quick update, since I'm tired...

I too the brake drums over to my friend's shop and put them on the lathe. They cleaned up OK, certainly good enough, so after leaving there after a couple hours' of shooting the shit, I headed to Harbl Freight and picked up a pneumatic nibbler, another angle grinder, and a couple other things we needed, and then swung by NAPA to pick up shoes and a hardware kit. Mike had to go out for a bit right when I got there, so in the meantime I sandblasted the outside of the drums and a couple other things, and then prepped and painted them.

Then I started work on the brakes. After stripping them down and checking the P/S wheel cylinder and not being able to move it at all, I took it off the truck and tried to get it moving. No dice, even with a small sledgehammer, and the other side is the same way. So later today I'll be picking up a set of cylinders so I can put the brakes together again.

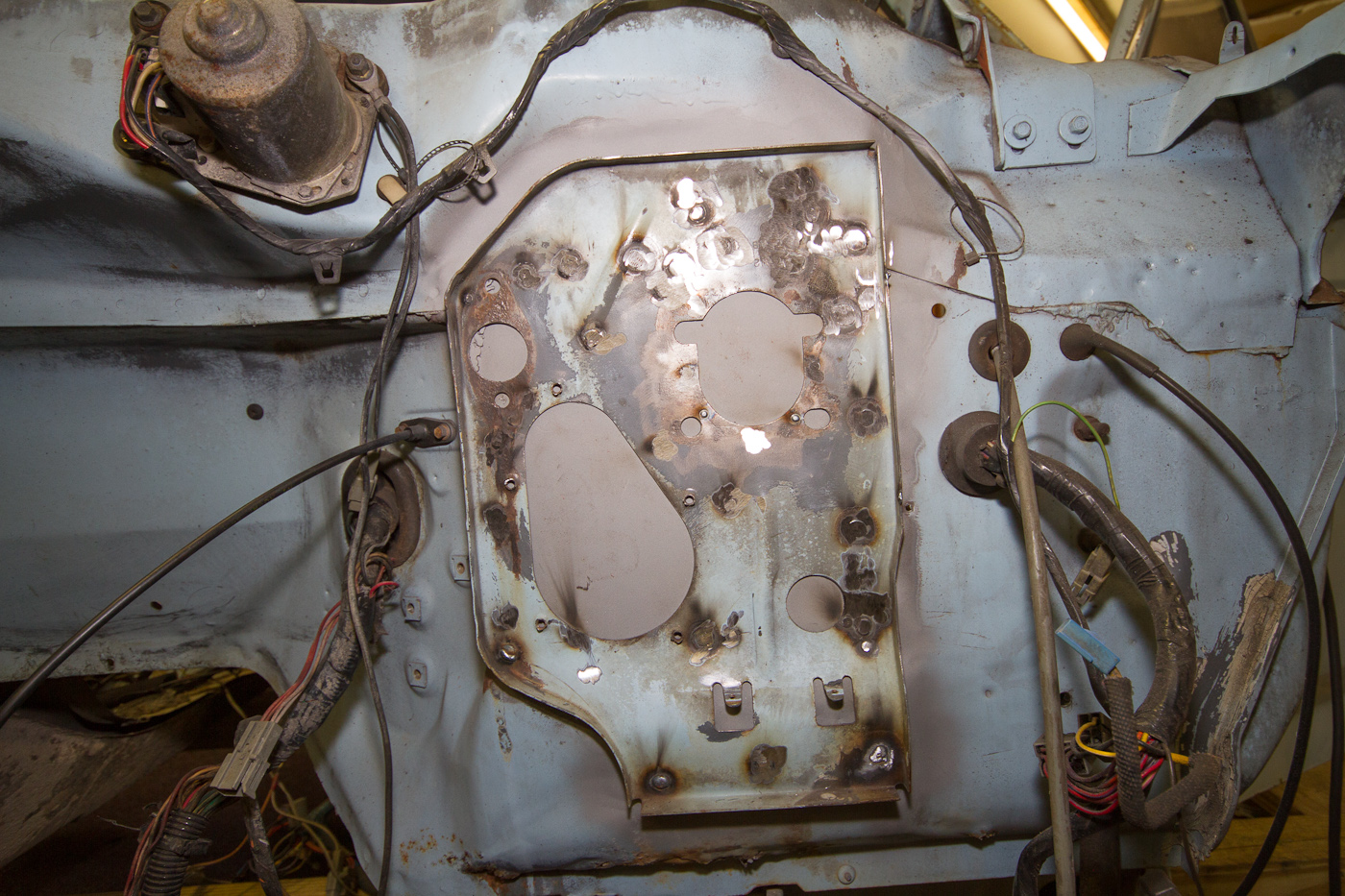

I also pushed the frame outside a bit and sandblasted the insides of the backing plates, which was really badly needed. Unfortunately, that proved to be the last thing the blaster wanted to do, because its handle split in two. I'm taking it back and getting another one later today, too. In the meantime, Mike got back to work on the cab, cutting out more rusted-through sections in the P/S door frame:

And also trying out the nibbler (which we wound up dismantling, slightly deburring and properly lubricating at the cost of almost 2 hours and multiple beers) on his new firewall piece...

After reaching a stopping point on the brakes, I decided I was sick of my floor jack being a pain in the ass to use and not wanting to work half the time, so I broke it down...

... and tore it apart.

I was able to replace the handle piston seals and the relief valve seal (all of which were leaking) but there are two more I need to source - the main reservoir seal, which is 2.5", and the shaft seal, which is 1". I'm gonna call the manufacturer in the morning and see if they can send me a seal kit. I think the cup seal on the end of the piston is OK, it looks fine, feels OK, and isn't dry or soft or anything nasty.

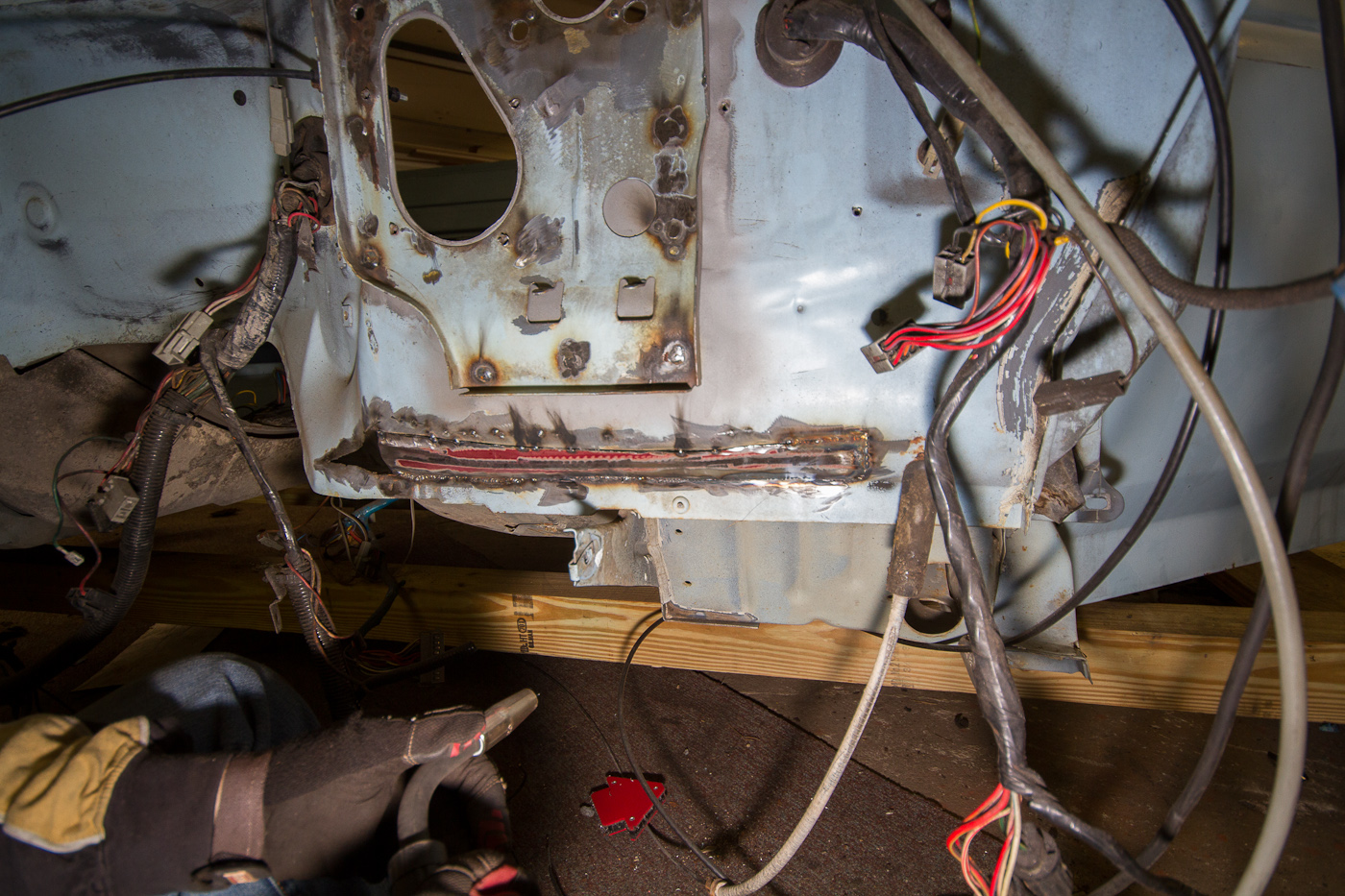

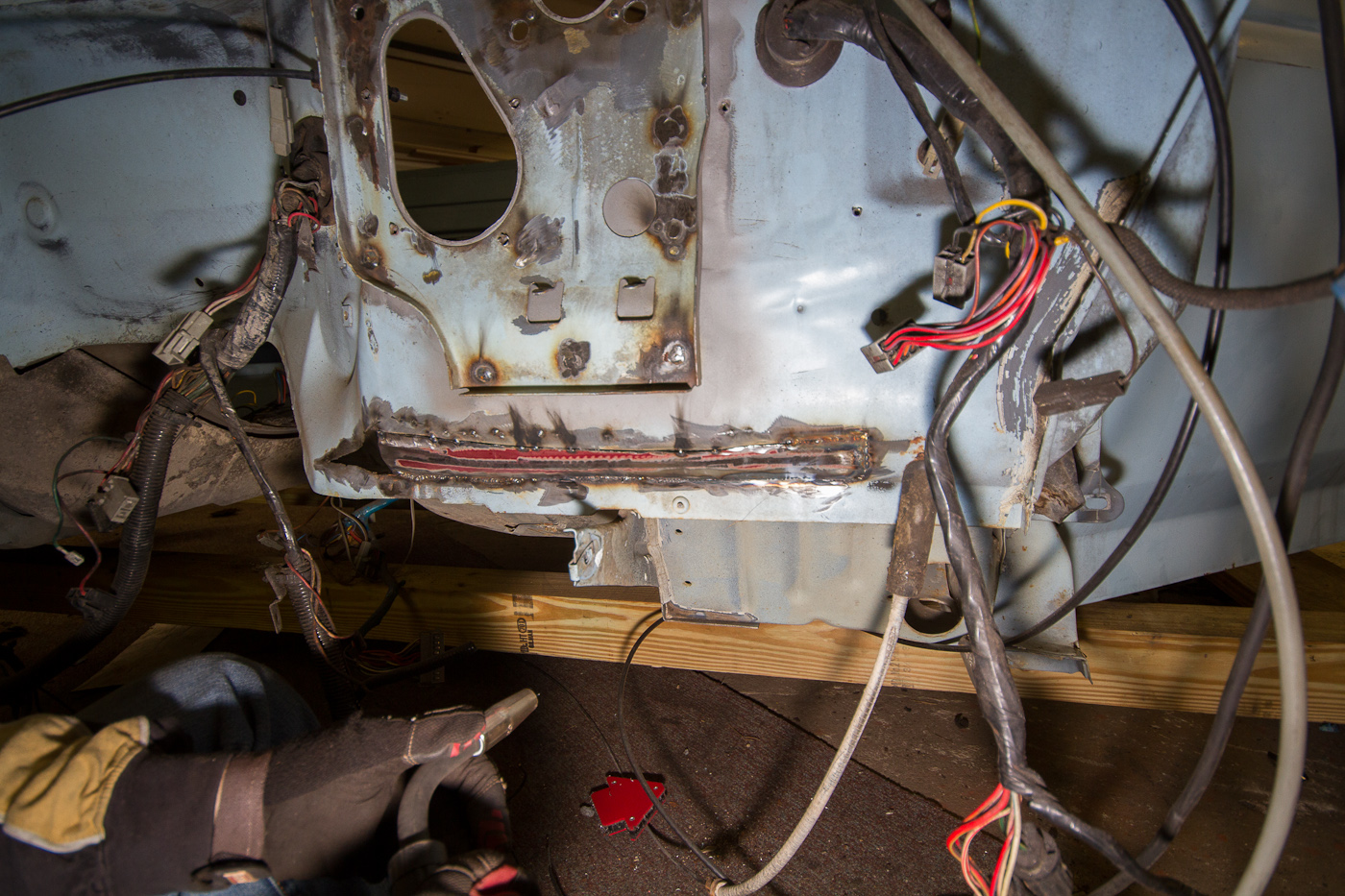

After giving up on that, we welded in the next patch panel, the little guy here near the bottom of the firewall. I also had picked up a set of these little guys (http://www.harborfreight.com/8-piece-bu … 44751.html) at HF at Mike's request, and they definitely came in handy, especially after a little QC with the grinder (removing slag, burrs, and stamping flash) to make them actually fit through the gap that was being welded. If you find yourself welding sheetmetal these are a good investment. This is after tacking the patch in place, but before fully welding the seams. The small missing piece at the end there is cut and formed, but waiting for a new sandblaster so it can be prepped for welding.

The only patches left to make are two small ones at the bottom of the P/S door, and two more on the floor. Once those are done and ground down, we'll have to roll the cab outside so I can sandblast it in suspect areas and sand the rest to get it ready for primer. It's conceivable that we could have at least part of the body done in epoxy primer by the end of this coming weekend. That would be awfully nice...

Official photographer/Team Police Brutality|Speedycop & the Gang

Lackey-mechanic-whatever/NSF Racing

Sycophant/Judge Phil, Jay Lamm, Kim Harmon

Galaxie Driver/not Parnelli Jones