OK, update time!

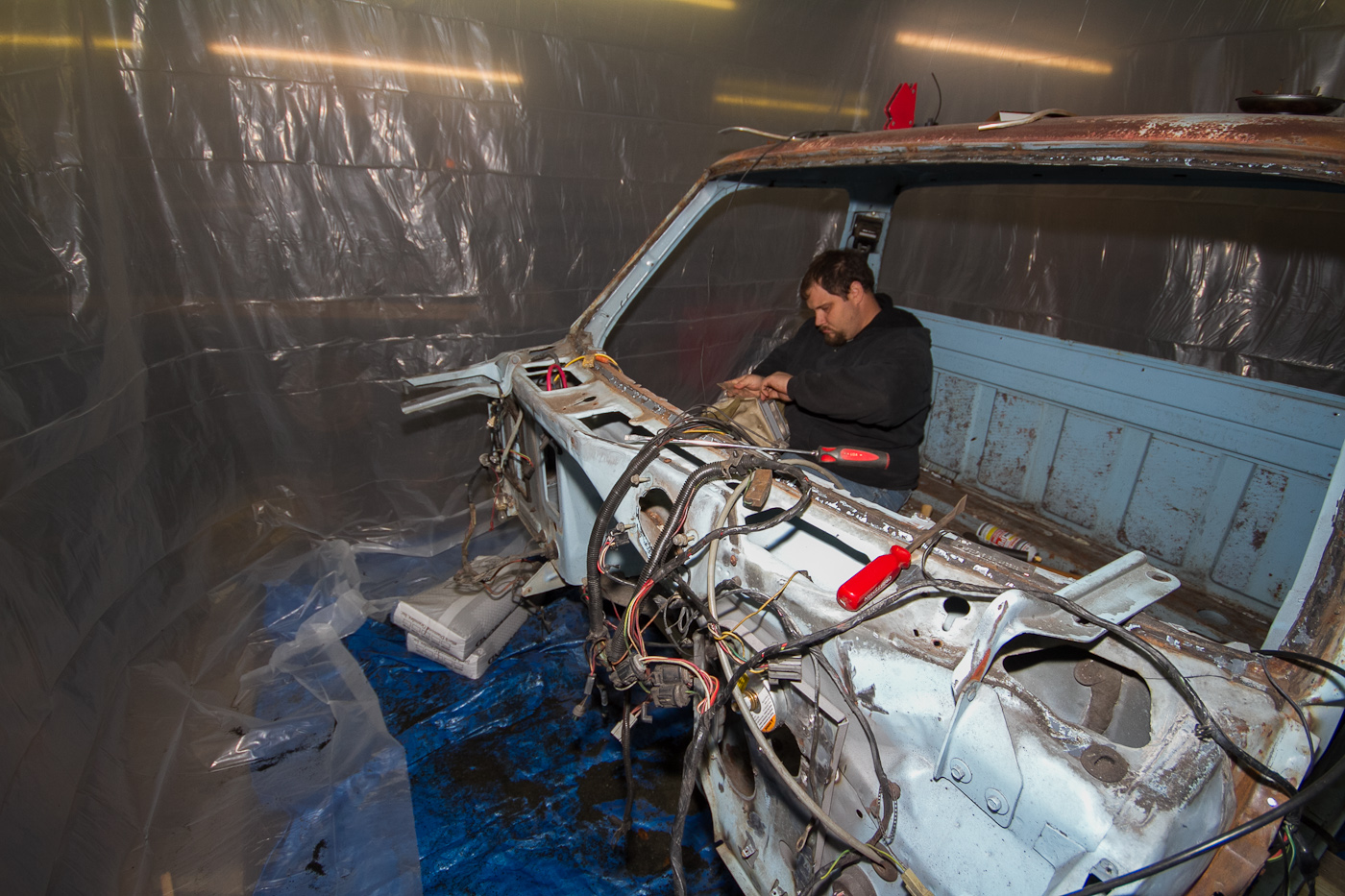

On Wed. (the day after I got back from Lemons racing in Texas) I went over after work. Mike had done a few things in the time I was gone, like finishing the roof and and finishing up the cab blasting I had left to do, but we still had a ton of work.

So first thing was to triage the p/s door sill rust. This rust turned out to be pretty contained to a small area, so we set about cutting out the cancer and grafting in some new metal...

Most of the bad metal cut out:

... and the patch panel cut and fitted:

Pretty straightforward welding operation with a piece that fits as tightly as this one. Mike enjoyed welding this piece, instead of having to try to bridge a 1/4" gap.

While that was going on, I was of course back in the sandblasting booth, this time with the core support and a few other pieces, getting them ready to go...

I had to work early Thursday morning, and was still pretty tired from the post-race drive home, so I called it a night around 10:30 and headed home. Mike stayed up another hour finishing the patch job and recreating the vertical metal the door seal sits on.

(this is tangentially related to the truck, so I'm putting it in here so you can see that we're not spending 100% of our time working on it, because shit happens)

Thursday at work I get a call from a friend whose Neon has been a thorn in my side for some time... I'm convinced she's just incapable of driving, since this like the fourth time in 3 years that she's hit something; the first three were other cars she rear-ended, this time it was a deer, and it broke the radiator, which I put in not much more than a year ago. She's been through this enough times to know what hissing and steam means, so she shut it off and had it towed home. And where I come in is, when your budget is as stretched by a project as ours is, you'll do anything for a couple bucks on the side, so with the new radiator in the trunk we brought the trailer over to her place and loaded it up. After spending some quality time with the tractor...

... and a small sledgehammer, the core support was more or less back in place and I could get the radiator out. I discovered that the fans were also busted, so those should get here from Rockauto tomorrow, and I'll put it back together Tuesday.

While I did that, Mike did some more welding, patching up pinholes in the floorboard wherever he could see light shining through. We really didn't get much accomplished, but we did get paid up front for the Neon, so there's that.

Friday was Mike's wife's birthday, so I didn't go over to work. Saturday they had more obligations, so we didn't do anything then, either. But today (Sunday,) finally, I was able to sweettalk Tim into coming over with me to do some work.

We started out by gingerly sitting the cab on its back, so that we could access the underside and get it ready for epoxy.

After a quick whack with the scrapers to knock the really heavy crud off, and the removal of the catalytic converter heat shields, we rolled it into the booth for (you guessed it) more sandblasting.

With relative ease (but not with speed,) 25 years of baked-on grease and dirt road mud disappear.

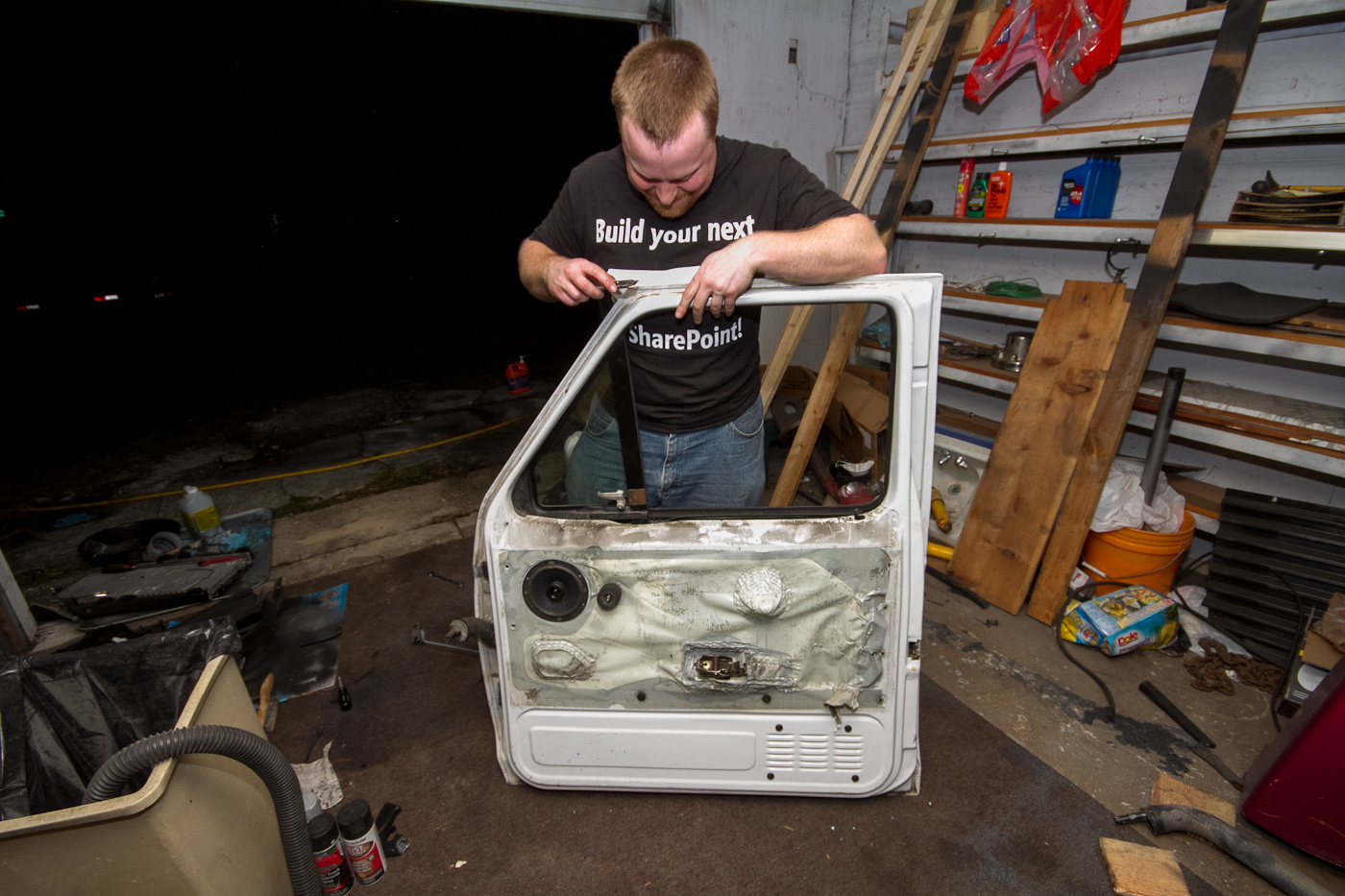

Meanwhile, Tim worked on cleaning up the pedal box (and then handing it off to me to finish-blast the main aluminum bit) and other metal bits and pieces, and painting them...

Converter heat shields:

While Tim worked on that, Mike was over on the other side of the garage, mounting the first of two 240V 5-ton AC fans into the paint booth. We've still got a long way to go on the engineering of the ventilation system in here, but this is the fan that's going to pull outside air in and (in my mind at least) distribute it down through a plenum mounted to the ceiling of the booth.

Welding also took place, as I got around to sandblasting some stuff other than the cab, and cleaned up the battery box. It had typical metal battery tray rust, so a patch was in order:

Much better.

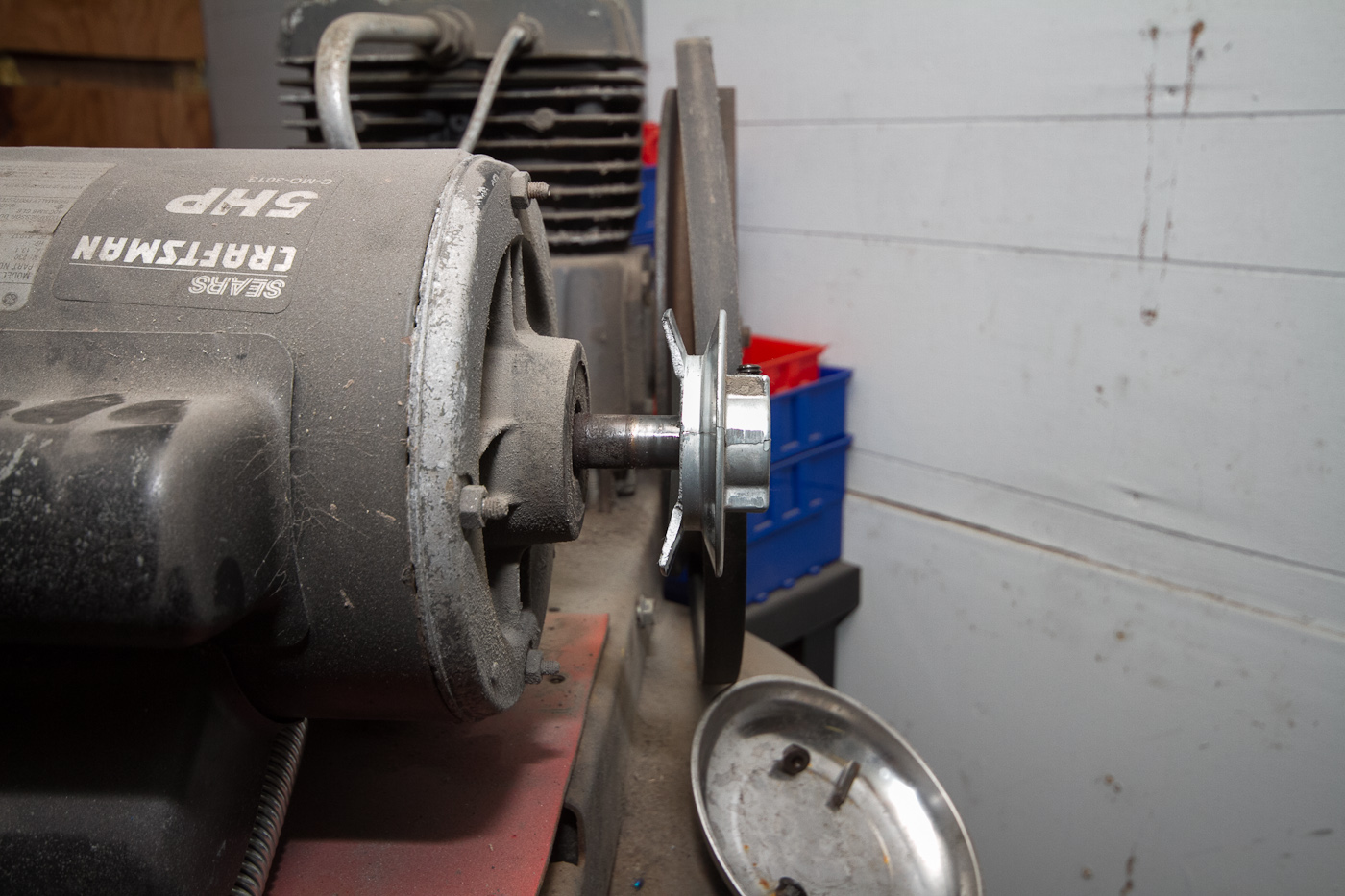

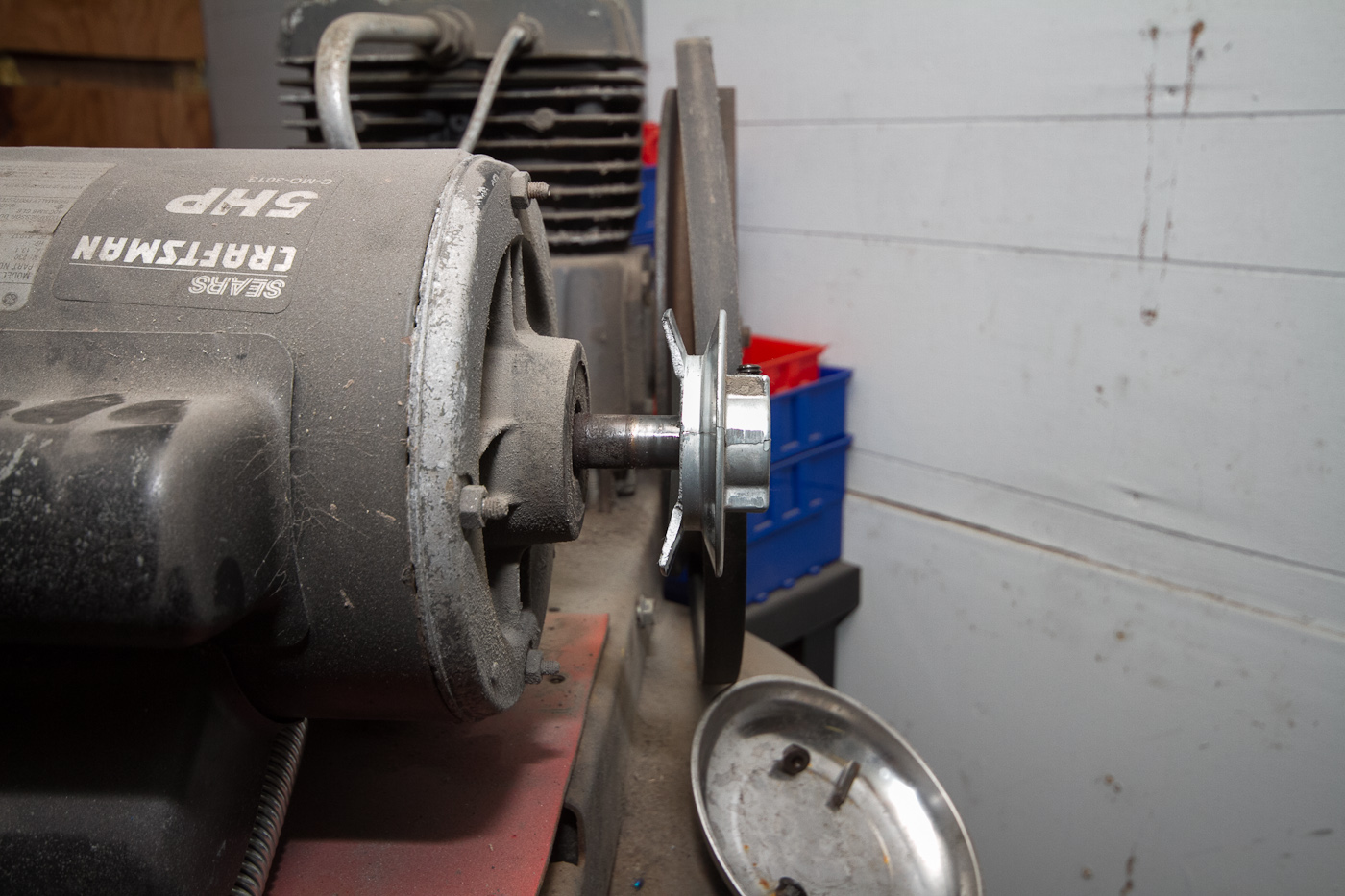

My blasting work on the cab pretty much ground to a halt when the air compressor started shaking violently around 10:30. Mike heard it and ran over to kill it, and we pulled it away from the wall and tried to figure out what was going on. It was readily apparent that the belt had jumped, but it wasn't til I went around to the other side that I saw this:

That's actually a US-made die-cast pulley, that very loudly came apart. I'll get another one tomorrow on the way out, and hopefully finish up the last bits of the cab underside as it sits now.

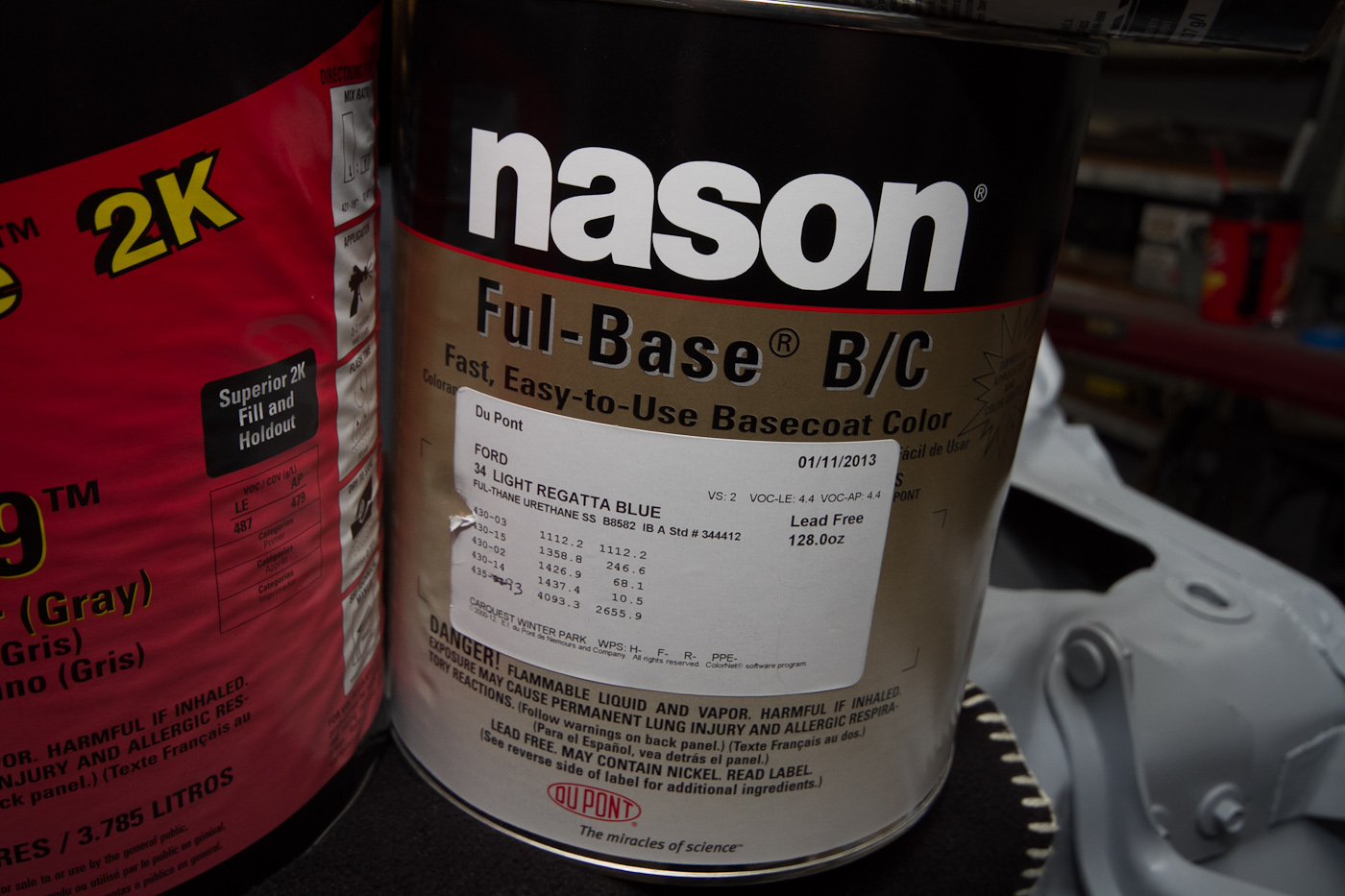

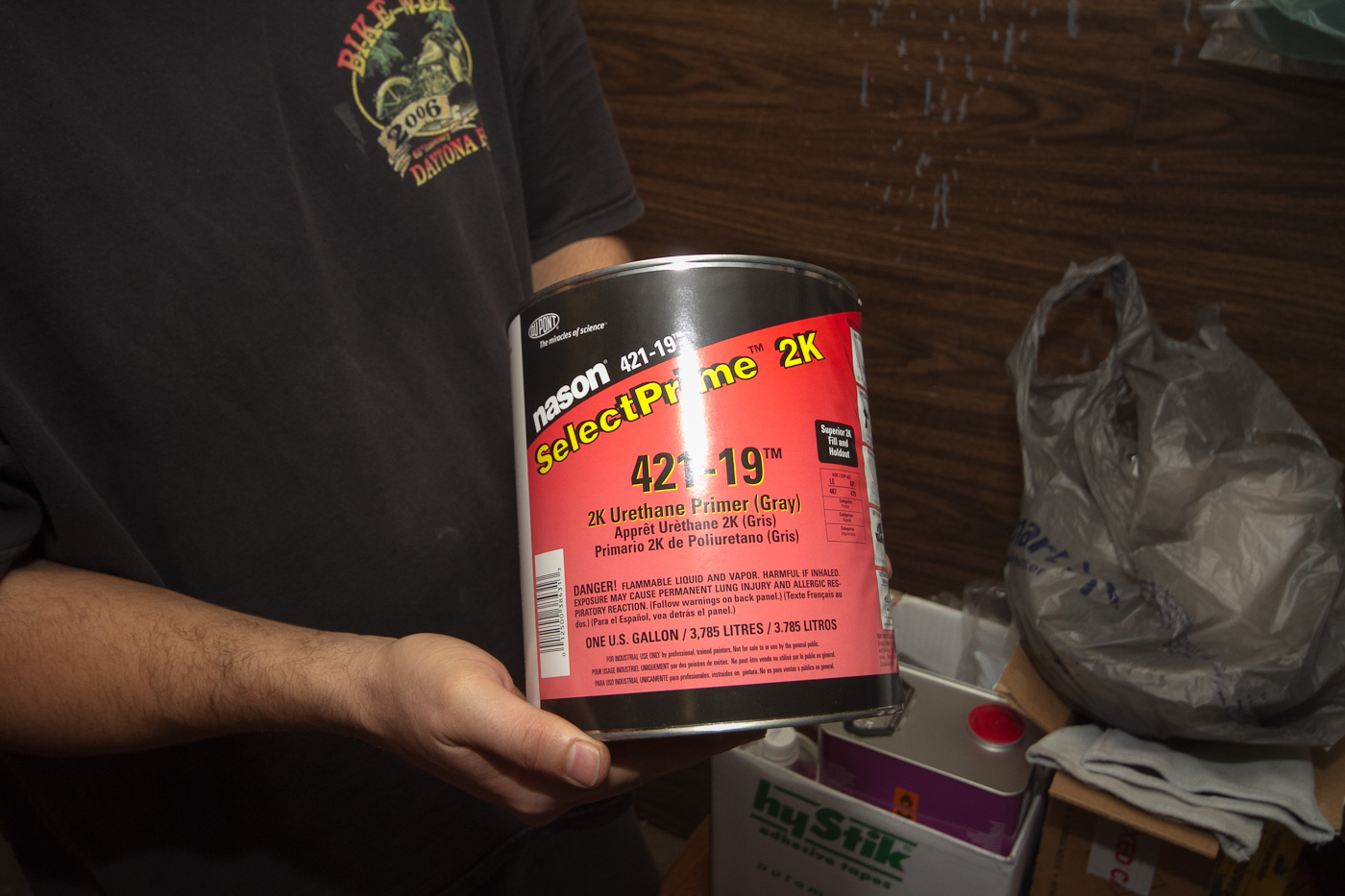

Oh, and actually something did happen Saturday. Mike went to the Carquest body supply store and got a few things, like the body filler:

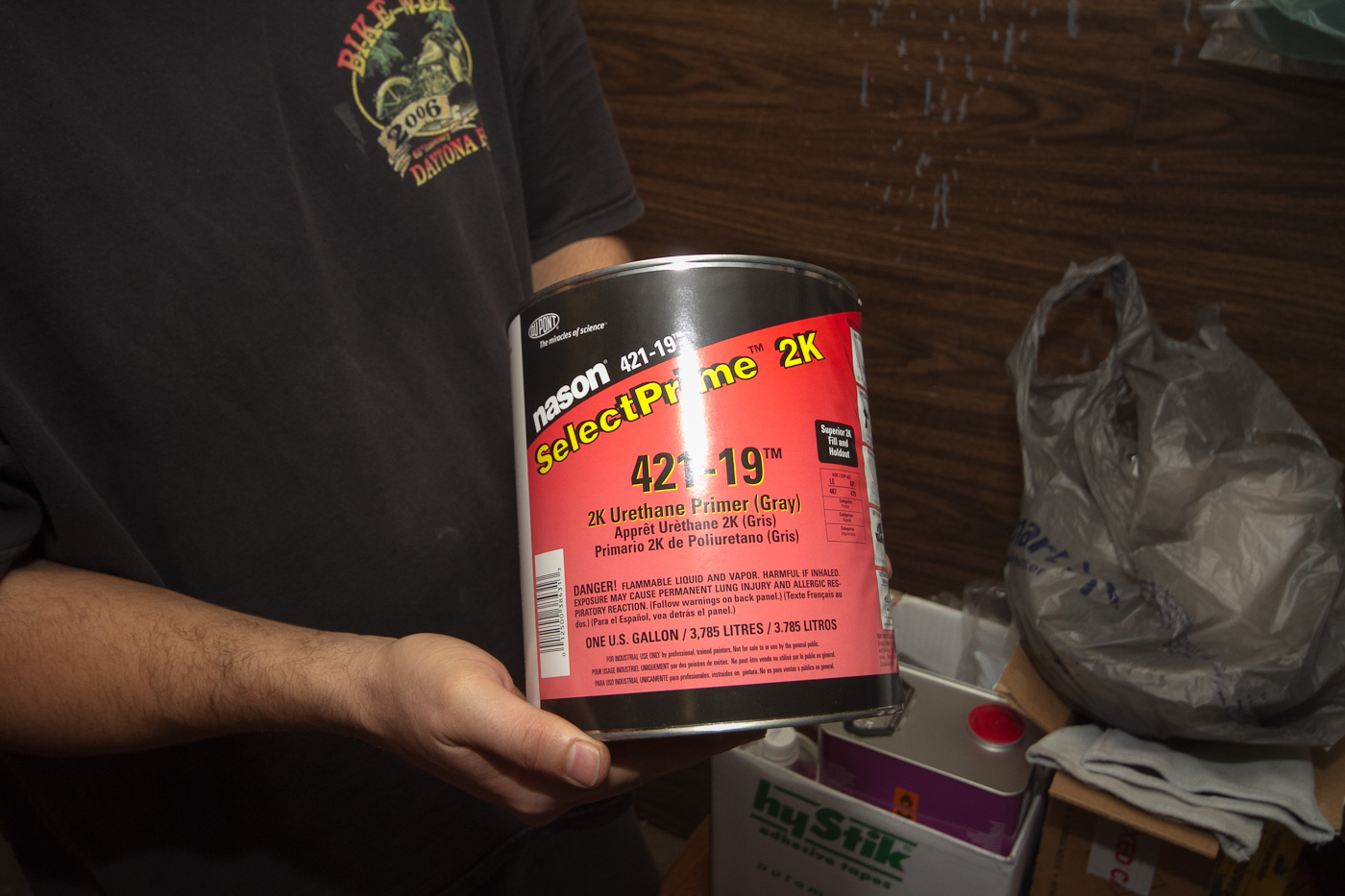

... and the urethane high-build primer, to go over the epoxy:

... and, to satisfy my friend Robert's strong warnings, some black-oxide grade-8 studs, with brass bolts for the exhaust.

Tomorrow I'll get the cab bottom finished, and hopefully fully cleaned and ready so we can hit it with the epoxy and sit it back on its bottom and work on cleaning and prepping the rest of the cab for epoxy. We're going to use the full-thickness alkyd enamel tractor paint on the bottom, and just roll it on instead of trying to spray it on. The extra thickness should help out NVH a little bit, too.

Official photographer/Team Police Brutality|Speedycop & the Gang

Lackey-mechanic-whatever/NSF Racing

Sycophant/Judge Phil, Jay Lamm, Kim Harmon

Galaxie Driver/not Parnelli Jones