Scotty,

Thanks for the compliments, there are a few reasons why i am not going that way. i think i've listed them in the past but i'll list them again:

1)I have an irrational hatred of all things automatic. everything from the wife's car, to the tow rig is a manual transmission. if i ever lose a leg, i'll put in hand operated clutches in my vehicles  this is for a few reasons, it's more fun to drive, having a clutch allows you do direct the braking bias a bit using engine braking and more importantly, before i did this i used to do offroading and automatic transmissions are always causing all sorts of issues there. I've had them catch vehicles on fire before becuase the oil gets too hot. I've had torque converters prevent me from getting up hills because they start sucking air. yes, modifications can overcome that, but you're still just applying a band-aid to the problem. the only thing i'd consider is if i had a manual transmission that had an extra gear between 1st and 2nd (closer to 1st) that transmitted the power through a torque converter. but only in that gear.

this is for a few reasons, it's more fun to drive, having a clutch allows you do direct the braking bias a bit using engine braking and more importantly, before i did this i used to do offroading and automatic transmissions are always causing all sorts of issues there. I've had them catch vehicles on fire before becuase the oil gets too hot. I've had torque converters prevent me from getting up hills because they start sucking air. yes, modifications can overcome that, but you're still just applying a band-aid to the problem. the only thing i'd consider is if i had a manual transmission that had an extra gear between 1st and 2nd (closer to 1st) that transmitted the power through a torque converter. but only in that gear.

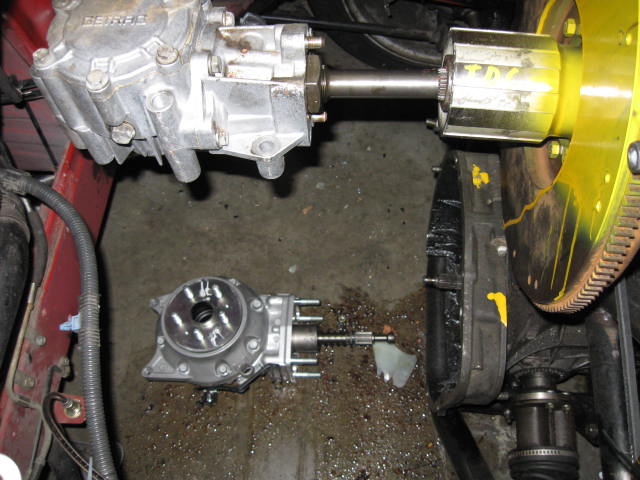

it's hard to be stupid like this with an auto:

2)from the technical side, using a torque converter is not nearly as easy as it is said. you have to provide coolant flow in and out of it concentrically through a shaft, at a minimum you have to have a way to drill two holes into a shaft offset from each other that don't touch each other or the outside and then you have to feed them through a rotary coupler of some sort that has to put up to high pressure and high RPM. then the whole assembly has to be held very concentric to the input shaft of the transmission to prevent the seals from being excessively side-loaded.

3)a belt that puts up to this stuff does not exist outside of the funny car supercharger world. have you ever priced one of those? the cog pulleys i'd need to achieve the 3:1 ratio also don't exist, more custom stuff to make. and then, we still have the issue that the rotation needs to be reversed.

I'm not saying these things aren't possible. but I think you guys overestimate the tools I have access to. I've got a CNC shop here that i can send work to, but other than the one side of the angry hamster box and the new output shaft for that box, everything else was done on manual mills and manual lathes of a few different sizes.

and yes, my Wife is awesome. I proposed to her on a wide-open baja trip (with a manual transmission and she also drove):