Re: Never before has so little power been made from so much displacement!

Oh, great. A guibo. Seen a lot of BMW guibos fail in Lemons.

The 24 Hours of Lemons Forums → The Airplane-Powered MR2 → Never before has so little power been made from so much displacement!

Oh, great. A guibo. Seen a lot of BMW guibos fail in Lemons.

Oh, great. A guibo. Seen a lot of BMW guibos fail in Lemons.

it's a used guibo also!

i need something to take up the hammering, but this will only be exposed to a fraction of the torque that a normal guibo is exposed to.

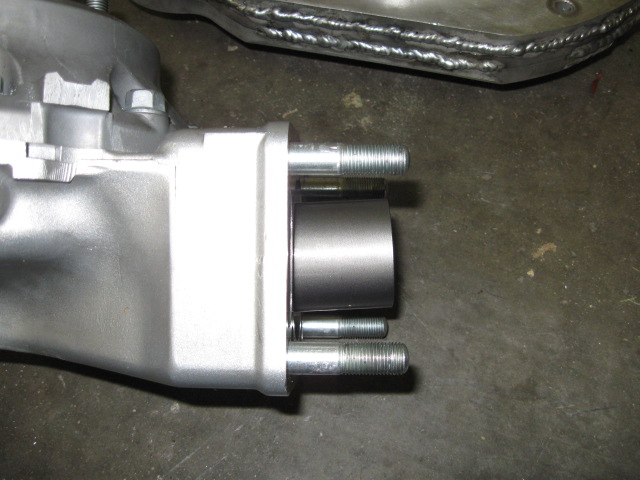

it's the flange to weld on the prop flange that will drive the BMW guibo. since i can't insert the bolt and i have to use a threaded interface, i made two sets of holes so i can remount it if it breaks off and damages the threads.

I absolutely love that you designed the part with a failure/repair mode in mind.

p.s. nice to meet you at Gingerman, hope to see you and your creations out again!

Marc wrote:it's the flange to weld on the prop flange that will drive the BMW guibo. since i can't insert the bolt and i have to use a threaded interface, i made two sets of holes so i can remount it if it breaks off and damages the threads.

I absolutely love that you designed the part with a failure/repair mode in mind.

p.s. nice to meet you at Gingerman, hope to see you and your creations out again!

oh, there will be more creations in the future. i promise ![]()

I've got a 2nd gen MR2 chassis and a corvette c5 frame & suspension waiting to become Lemons. this is a never-ending game! ![]() I've also got my eye on a buick roadmaster that would make a great chassis for a twin or tripple V8 build. if i could get a dana vee drive i could see shoving 4 engines in there.

I've also got my eye on a buick roadmaster that would make a great chassis for a twin or tripple V8 build. if i could get a dana vee drive i could see shoving 4 engines in there.

i need to figure out a way to get paid to do this stuff. anyone hiring a professional madman?

Getting paid to do it is what most are trying to figure out. Best chance I think anyone has is Jay selling out and getting nascaresque broadcasting. With that get sponsorship deals and have some money. Of course within a couple years big names will be in Lemons making it so the original teams will be shuffled aside and we won't have money or a series to race in.

Getting paid to do it is what most are trying to figure out. Best chance I think anyone has is Jay selling out and getting nascaresque broadcasting. With that get sponsorship deals and have some money. Of course within a couple years big names will be in Lemons making it so the original teams will be shuffled aside and we won't have money or a series to race in.

it was more of a joke than anything. but if you look out west where they get to pick & choose who shows becuase they have too many entrants they really stress theme instead of big money spenders. Jay would have to change the outlook on the type of car he wants to show up for the little guys to be bought out of the series.

I'm sure coverage will increase over time. it is a rather spectator friendly sport after all. and yes, that probably means some people will start to get legitimate sponsorships in order to get some camera time but i don't see that being a terrible thing that will ruin everything.

heck, if anything we should get together and put up a few cameras here and there on the track until the real camera people show up. we have an in-car camera transmitted live back to the pits at the moment and it makes the whole thing a bunch more fun. but if we had another 6-12 cameras showing some of the corners on the track it would give everyone at the track something to do. i suspect if you were planning on letting everyone view the signal instead of holding it to yourself the track would let you plant a few light cameras on lightweight sticks out near the track. nothing that can really injure people if they get hit.

I call dibs on all Bacon, Tampax and Vegamite.

but this will only be exposed to a fraction of the torque that a normal guibo is exposed to.

Fraction of the torque. On the prop flange of a radial engine.

I don't care if it's true, it sounds absolutely ridiculous and I love it.

Marc wrote:but this will only be exposed to a fraction of the torque that a normal guibo is exposed to.

Fraction of the torque. On the prop flange of a radial engine.

I don't care if it's true, it sounds absolutely ridiculous and I love it.

but it is. if we look at modern engines and the torque they produce you tend to get no more than 75lb*ft per liter (for N/A) so even if for some reason, the fuel injection setup i did hits the dead nuts perfect sweep spot (and it does not) we're looking at 666lb*ft of torque and let's say it's flat across the band because that's the worse case. the least torque it could have is probably what the carb'd and no timing advance made and that would be about 600lb*ft at idle and about 400lb*ft at 1950rpm.

and that's in, no gear reduction or anything. the guibo sees no more than 666lb*ft at any given point (maybe under hard decel, but this engine has no compression so even then i doubt it's over 666lb*ft.

this perticular guibo is from a 533i e28. it probably is the same part number behind bigger motors, but let's just assume this case. it made 181hp and 195lb*ft

the gear ratios:

1-3.83

2-2.20

3-1.40

4-1.00

5-0.81

which means max torque in gear:

1-747

2-429

3-273

... oh crud!

hmm, that does paint a pretty sad picture. this might not be a manly enough part. damn those E28's had pathetic motors!

now the good news is, if i look at a modern application for this exact same joint, it's on the current model X5 with a torque output of 302lb*ft in it's smallest configuration (just in case the joint does not apply to all engine options) that perticular configuration can apply just as much twist to that guibo until the end of 3rd gear. if we look at the bigger engine options, we can pick up 4th and 5th before there's less twist on that part, but i bet the 'M' version gets a different joint.

all that to say, i believe i'm within the operating parameters of the part. but i do not have as much margin as i thought i did.

a neat thought is, if i were to magically get to that high torque number and sustain it, i'd have 250HP ![]() WOO!

WOO!

just putting together a to-do list to organize myself and figured i'd post it:

-prop nut flange (sent out for mfg, ARP bolts ordered)

-prop nut (have tap, need to get more precise taper angle, will work on it tonight)

-machine down back plate of angry hamster box to be flat and add a bolt flange pattern to it.

-make adapter tube to adapt the above bolt flange to a goldwing final drive pattern. make oil tight with a vent and hold an extra bearing. bearings need to be rated for 6000RPMs

join goldwing driveshaft with custom crankshaft flange (the existing but broken one)

-E153 countershaft nut needed to hold guibo flange on 3000GT box

-make mounting plate to attach 3000GT box to body at left and right engine mounts and firewall strut bar mounts. the mounting plate should contain a scatter shield for the upper driveshaft joint.

-make flange that adapts 1310 joint to goldwing wheel flange

-make driveshaft

-tweak clutch to get it to fully release (i think the disk needs recessed in the flywheel about 100thou or so, consult fort wayne clutch for help.)

-make scatter shield or at least a hoop for the bottm driveshaft joint

-reroute vents on 3000GT box and on goldwing box.

-fix rear window on MR2

-race the heck out of it!

*edit* maybe think about getting the tach working also. right now it just has a head temp sensor that can't be read when the engine is running since it shakes too much and a fuel guage

well, another thing almost off the list (minor tweaks still needed, but almost done)

i worked on the prop nut tonight:

the idea is to use an air chisel with a blunt tool to tighten it and then drop a mushroom shaped pin in the hole through the crankshaft retained by those 2 o-rings to stop of from coming loose from the vibrations.

here's an assembled picture:

*edit* maybe think about getting the tach working also. right now it just has a head temp sensor that can't be read when the engine is running since it shakes too much and a fuel guage

Found the solution to the gauge shake. Courtesy of Gizmodo and NASA. If you don't have a digital gauge, check your local aircraft salvage company. Digital EGT monitors should be cheap enough since you don't need them flight certified.

Marc wrote:*edit* maybe think about getting the tach working also. right now it just has a head temp sensor that can't be read when the engine is running since it shakes too much and a fuel guage

Found the solution to the gauge shake. Courtesy of Gizmodo and NASA. If you don't have a digital gauge, check your local aircraft salvage company. Digital EGT monitors should be cheap enough since you don't need them flight certified.

i remember reading about the strobe thing a few years ago. damn neat solution to the problem ![]()

this isn't that, it's just that i got a Lemons grade CHT gauge that cares more about gravity and vibration than the actual temperature on the probe. a cheap digital CHT gauge will be fine. or i can wait for the straits to check it.

this isn't that, it's just that i got a Lemons grade CHT gauge that cares more about gravity and vibration than the actual temperature on the probe. a cheap digital CHT gauge will be fine. or i can wait for the straits to check it.

Marc, if the gauge cares more about gravity than the input, the pointer assembly is out of balance. If you're interested, I can probably walk you through a balance procedure. I may even be able to calibrate the thing (depending on manufacturer and part #) if you are interested in sending it to Seattle.

Marc wrote:this isn't that, it's just that i got a Lemons grade CHT gauge that cares more about gravity and vibration than the actual temperature on the probe. a cheap digital CHT gauge will be fine. or i can wait for the straits to check it.

Marc, if the gauge cares more about gravity than the input, the pointer assembly is out of balance. If you're interested, I can probably walk you through a balance procedure. I may even be able to calibrate the thing (depending on manufacturer and part #) if you are interested in sending it to Seattle.

while i think it's likely a very mute point on this gauge, I'd love to know how to do that. do you do instrumentation for a living?

the gauge is this one: http://www.vdo-instruments.com/instrume … ature.html part:310 033

it's a K type thermocouple with a 100-600F range so it's effectively a volt-meter that has very high impedance with a full scale range that starts at 0.003184V and ends at 0.012915V (a range of 9.7mV). it's also important to note that there is no amplifier on board (no power source) so that voltage range drives the needle directly.

but please tell me more about calibrating gauges, if you want to send me an e-mail we can take this discussion offline.

Thanks!

i spent a few hours in the shop last night, sorry forgot to bring the camera.

i was working on the adapter piece between the clutch and the goldwing final drive and while i did get something good enough to prove out the idea, it became obvious that the only way to get this piece strong and strait enough will be to make it out of a solid chunk of metal. I'll probably use aluminium to make it easier to machine and since there's no need for thin teatures.

also, last night marked a new milestone in this project. it was the first part i made that i said "screw it" to making it serviceable. i did not have a snap-ring of the right size to make the assembly possible to dissemble so the "crankshaft flange to goldwing spline" piece is permanently mounted in it's plate now.

the other concern is once i shimmed out the flanges to correct for the warp and everything was moving smooth with no binding it really demonstrates how high the goldwing box ratio is. i'm concerned that the subaru flywheel load on the system might be a bit high.

one thing that is a very happy coincidence on that goldwing box, it does vent out through the spline interface so i can just block the vent on the box and add one to the interconnecting piece with a proper orientation.

a final note was the current clutch's state. it was a new clutch and it seems about 1/2 worn out. i hope that's because the alignment went to crap after parts started breaking and not because of the motor's power delivery in big strong pulses. I'm thinking of pulling a bunch of timing out at the bottom of the RPM range to drop the torque down there. it'll cause a bit more heat but there's probably a decent balance to strike.

stimpyvan wrote:Marc wrote:this isn't that, it's just that i got a Lemons grade CHT gauge that cares more about gravity and vibration than the actual temperature on the probe. a cheap digital CHT gauge will be fine. or i can wait for the straits to check it.

Marc, if the gauge cares more about gravity than the input, the pointer assembly is out of balance. If you're interested, I can probably walk you through a balance procedure. I may even be able to calibrate the thing (depending on manufacturer and part #) if you are interested in sending it to Seattle.

while i think it's likely a very mute point on this gauge, I'd love to know how to do that. do you do instrumentation for a living?

the gauge is this one: http://www.vdo-instruments.com/instrume … ature.html part:310 033

it's a K type thermocouple with a 100-600F range so it's effectively a volt-meter that has very high impedance with a full scale range that starts at 0.003184V and ends at 0.012915V (a range of 9.7mV). it's also important to note that there is no amplifier on board (no power source) so that voltage range drives the needle directly.

but please tell me more about calibrating gauges, if you want to send me an e-mail we can take this discussion offline.

Thanks!

First of all, I apologize in advance for the length of this post. Secondly, this information is kind of plain vanilla. Bi-metal thermocouple indicators have been around a long, long time (since at least WW2) and there are a LOT of different methods that they have been used & without seeing the instrument in person, I am very leery of being too specific.

Yes, I've worked in the aviation industry for a long time. The voltages you posted seem wrong for a K-Type thermocouple. Do you know what material the leads are? Chromel-Alumel (red-yellow) are pretty common, but there are several other combinations.

Also worth keeping mind is that the length of the thermocouple leads used in the installation are important as their inherent resistance can greatly affect the accuracy of the instrument. If you have shortened the leads, the instrument will indicate higher. Longer leads result in lower indications. If you have lengthened the leads by adding copper wire, you have added 4 new thermocouples to the circuit and you're screwed.

Meter movement balancing and calibration are two different things. Balancing is relatively straightforward but calibration requires either specific test equipment (Fluke 714) or an ice bath.

To balance, you will need something similar to the Fluke mentioned above or a millivolt source and a DMM that is accurate into the microvolt range (350 F on that gauge should require an input of 7.207 millivolts). In a pinch, you can do without the accurate meter though. You just need to be careful not to over-volt the CHT gauge.

Probably the easiset way to make a millivolt source is by using an AA battery, a couple of fixed value resistors, and a variable potentiometer capable of very fine adjustments (10 turn 5K ohm is great if you can find one).

You can check balance without opening the housing on the instrument (& this is what I suggest you do).

If you are going to open the instrument, be very careful! This type probably uses a hairspring suspension for the meter movement. Do not touch the hairspring! They are very fragile and they can get tangled easily. Untangling them is possible, but requires a lot of patience and some pretty expensive tweezers. Also, if you open this thing, the area you open it in needs to be extremely clean. The magnet in the meter movement is pretty strong and will pull ferrous material into the meter's air gap and cause all sorts of grief. NEVER use any kind of compressed air or spray solvents to clean the thing. If you have decent magnification available, take a look at the hairsprings. They should form a nearly perfect spiral.

Also, if the meter has adjustable end stones/jewels, resist the temptation to adjust them. The correct window of adjustment on these is typically in the neighborhood of .0001" and if you don't know what you're doing, hitting that window is almost impossible.

To check the balance:

1) Align the meter straight up and down (left to right and front to rear). Brace the in the instrument so that it can't roll (our high tech solution is a 2X4 with a "V" notch cut into it. Whatever you use, it needs to be non-ferrous).

2) Drive the meter until it is exactly at center scale.

3) Rotate the instrument 180 degrees clockwise so that the center scale or index (not necessarily the pointer) is straight down.

4) If the pointer is still pointing directly at the center scale or index, your Left/Right balance is good. If the pointer is not pointing at the index, skip down a bit.

5) Roll the instrument 90 degrees counter clockwise so that center scale or the index is pointing directly Right. Note the position of the pointer.

6) Roll the instrument 180 degrees counter clockwise so that the center scale or the index is pointing directly Left. Note the position of the pointer.

7) If the pointer is accurate in both these positions, Top/Bottom balance is good.

If balance was good Left/Right and Top/Bottom, immediately reassemble the instrument without screwing anything up.

If you do check your balance and find that it is out, let me know and I can give instructions on how to fix it. I will need pictures of the meter movement itself though. There are a lot of differenct balancing schemes and trying to cover them all would be difficult.

If you have any questions, please don't hesitate to ask.

I don't mind answering questions in the forum but if you want to email me that's fine too; van at speedchimp dot com

Cheers!

hmm, the first thing that comes to mind with what you said. the leads on this thing are only about 10" long but the gauge came with about 15' of copper wire with the ends already crimped on. i used the whole thing as-is

the temperature when steady does look about right. it behaves like a normal air cooled motor, but who knows if this motor from the 30's behaves like a normal modern air cooled motor.

I'll go through the procedure above when i get a bit of spare time. Thanks!

If the instrument came with leads, it should already be calibrated to match them. As long as you don't shorten (or try to lengthen) the thermalcouple leads, you should be good.

I believe that the copper wires will only be for backlighting. I can't imagine what else they would be for. Length of those should not matter.

I assume you are going to use the CHT to ensure you don't go lean with the motor, but is there a reason why you are using that instead of an EGT?

I'll warn you that it has been 20 years since I've dealt with radial engine stuff, but I believe that the air racers (T-6 Texan pilots) we worked with all replaced their CHTs with EGTs because EGTs reacted to mixture changes so much quicker (since exhaust gas changes temp almost immediately and cylinder heads have a lot more thermal mass to heat or cool). They may also have augmented their CHTs with EGTs. I can't remember exactly. I do know that they were required to have all the original instruments for the front and rear seats so they routinely had us remove all the internal components to lighten the aircraft (Why remove 10 Lbs of weight from a 2 ton airplane? Because race plane.) and the CHTs were pretty heavy.

If I remember correctly, the reason CHTs were used originally was because a thermalcouple that could withstand exhaust gas temperatures wasn't available (the older CHTs I have seen used an iron-constantan thermal couple).

If you want, I can give an old co-worker a call and see what he knows. He routinely supports T-6 Texans that race in Reno, so he would probalby know if there is any reason to run a CHT instead of an EGT. Or if you are way better off running both.

the mixture is monitored with a wideband O2 sensor and controlled with fuel injection. that was so many hundreeds of posts ago, you may not have seen it. there's no gauge on that because i let the computer do it's computer thing. though it does need a bit more tuning also.

the CHT sensor is just to make sure i'm not cutting too much airflow to the engine and overheating it. as long as the CHT stays below 550F the motor stays happy (according to this manufacturer book)

For a lemony solution, to your CHT gauge issue, many inexpensive digital voltmeters have a temperature function that reads a standard K-type thermocouple. if your CHT pickup is K-type, you can just plug it into a voltmeter that you can ziptie or attach by some other method to the dashboard. the digital meter won't be affected by vibration. Although you may have trouble finding one without an "auto power-off" function.

Plus, with a digital meter, the input impedence should be very high, so the thermocouple isn't really required to put out any drive current, like it would for an unamplified mechanical meter, so it should be much less sensitive to lead lengths.

the drive ring came in:

it even fits!

ok, the intention was for a very slight press fit and it ended with a tight slip fit. close enough for what we are doing here.

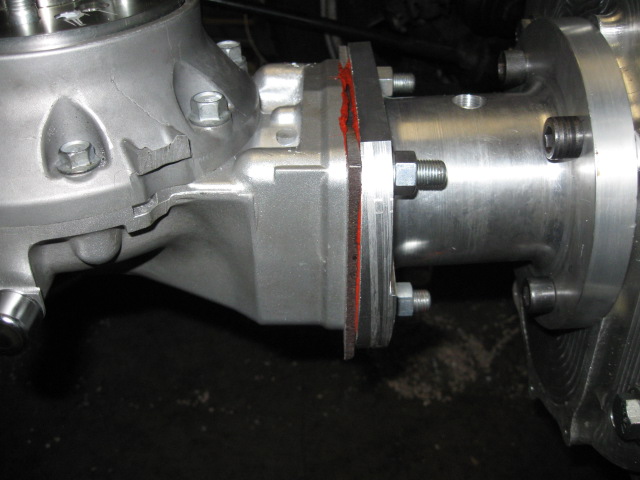

shaved down the back side of the angry hamster box and made a coupler to attach the goldwing box to the clutch:

that adapter housing is a bit annoying. i've built it twice now, the first time was a weldement that i thought was crooked. so i said screw it and just made the new one from a decidedly un-lemony giant block of aluminium to guarantee everything would be as strait as possible. imagine my surprise when the new one does not fit any better. turns out, the shaft is not normal to the mounting surface.

it's bad enough you can see it with the naked eye:

so now i have to make some kind of angled shim to deal with this.

I got to spend most of today in the shop. I'm pretty excited about the progress.

1st, i finished the prop flange and the prop nut, it kills me that this simple prop nut locking method hadn't occured to me earlier:

(it's not copper, it's mild steel tig filler rod)

then, i fixed the angle on the goldwing final drive. if anyone ever needs to know, it's 3.25 degrees (well, i measured 3.21 and assumed 3.25)

i did need to add a spacer to make up for the lost thickness when i cut the angle into the adapter. that was 2 hours of my life on the surface grinder that i simply won't ever get back. i'm not sure who the heck ever thought that a surface grinder would work just fine with 100% manual controls.

i then went to fort wayne clutch and talked about the release problem i'm having. they checked everything and said that it all looked good. we measured the release distance on the clutch and i definitely have enough travel. I'm starting to think that the release problem was due to the shaft being broken inside the angry hamster box instead. maybe it was broken before i even ever went for the first lap out there.

if it still has release issues I'll switch to a ceramic button clutch. they disengage with a bit less travel.

so i mounted all that stuff up together:

the threaded hole on the adapter is for the goldwing and the flywheel's bearing oil they share oil and this puts the vent at the right place. i just need to block off the other vent so it does not leak.

and then, for grins i threw the other box on top there to make sure the distances look reasonable:

I'm excited! I'll try to build the mount for the 3000GT box tomorrow.

i did need to add a spacer to make up for the lost thickness when i cut the angle into the adapter. that was 2 hours of my life on the surface grinder that i simply won't ever get back. i'm not sure who the heck ever thought that a surface grinder would work just fine with 100% manual controls.

That is one of life's great mysteries. I had an opportunity to get a manual surface grinder for cheap, but I turned it down. I figured that it would be a better investment to pay a shop to do my grinding, rather than sit at the machine for hours on end, getting bored out of my mind. At least with automatic feed I could do something else while it ran, even if it was just sweeping the floor.

Marc wrote:i did need to add a spacer to make up for the lost thickness when i cut the angle into the adapter. that was 2 hours of my life on the surface grinder that i simply won't ever get back. i'm not sure who the heck ever thought that a surface grinder would work just fine with 100% manual controls.

That is one of life's great mysteries. I had an opportunity to get a manual surface grinder for cheap, but I turned it down. I figured that it would be a better investment to pay a shop to do my grinding, rather than sit at the machine for hours on end, getting bored out of my mind. At least with automatic feed I could do something else while it ran, even if it was just sweeping the floor.

yeah, it sure seems like the raster pattern would be really easy to implement without using electronics. even if it did not return home afterwards, it would allow me to get a steadier sweep across the surface while doing something else more productive.

The 24 Hours of Lemons Forums → The Airplane-Powered MR2 → Never before has so little power been made from so much displacement!