Re: Never before has so little power been made from so much displacement!

Thank you for your brilliant addition to the thread.

The 24 Hours of Lemons Forums → The Airplane-Powered MR2 → Never before has so little power been made from so much displacement!

Thank you for your brilliant addition to the thread.

If someone has metal analysis equipment at their disposal. i'm willing to send off the lower sprocket so we can see just how much strength we're talking here.

it's an alloy so none of us really know what the strength truly is.

Marc,

I work for a global custom alloy fabricator. We have a lab that does nothing but test metal alloys to understand tolerances, failures, etc....

I'm sure the boys would love to take a look at the sprocket.

Marc wrote:If someone has metal analysis equipment at their disposal. i'm willing to send off the lower sprocket so we can see just how much strength we're talking here.

it's an alloy so none of us really know what the strength truly is.

Marc,

I work for a global custom alloy fabricator. We have a lab that does nothing but test metal alloys to understand tolerances, failures, etc....

I'm sure the boys would love to take a look at the sprocket.

sure, PM me an address. i'll send the shaft too if you can tell me just how far off i was on the ability for that shaft to carry the load.

Thank you for your brilliant addition to the thread.

Perhaps I misunderstood your misunderstanding, but didn't you say the jugs/heads were supposed to spin?

Maybe the weight of the cylinder jugs/ heads could be measured (since normally they spin)

I vaguely recall this being a topic of discussion at gingerman at dinner.

Seems there was an early radial rotary in which the motor did spin. Guess that would solve the flywheel problem huh?

FJ40Jim kindly illustrated in way too much detail that the large spinning mass acted as a gyroscope of sorts and made it sort of hard to turn the plane which was bad if someone was shooting at you.

What does this have to do with this thread? Nothing... I just figured as it came up and the topic slowed down the consumption of steaks and mixed drinks that everyone should have to pay the price with those of us who were there. ![]()

The thread hasn't been clear on the original use/ radial/ rotory of this engine.

I didn't look up its history....

I'm giving a helping hand with some technical mechanical ideas.

no harm no foul....

Manny.

You mean like the little Megola motorcycle?

What I think you really do need is a dual mass flywheel similar to that used on huge numbers of modern cars but probably with a greater degree of flexibility. Maybe something out of a diesel 4 speed small truck.

Find one in a junkyard and see if you can get a greater degree of motion out of it. Lighter springs and possibly modify the pocket size between them.

Check here for some info: http://www.standardtransmission.com/dmf.html

figured i'd give you guys an update. someone generously offered to use their facilities to analyze my sprocket wear and shaft failure.

I won't name him because i'm not sure if he wants me to, but it was an amazingly generous offer and i'll post the results when i get them back.

meanwhile, it looks like we'll be racing autobahn at the end of the summer. it would be nice if the new drive system is done by then but i make no promises, i'm not rushing this again.

not a very big update, but an update nonetheless:

picked up a NP236 transfer case over the weekend, it's almost identical to the NP246 we were discussing in here earlier:

the only potential issue is the spacing between the shafts is only 9.5" add the angry box spacing and i'm still shy 3" to get my shafts perfectly flat. so what i think i'm going to do is as follows:

put a dual mass flywheel on the airplane motor's output. probably from a 7.3L powerstroke but i haven't done much research there yet.

from the other side of that flywheel i'll attach a CV shaft. if i limit myself to a 10degree angle the joint to joint distance has to be about 17" long. that should be achievable. but 12degrees would be 14" long which is definitely doable and still in the proper range for a CV joint. the motor's 1900RPMs is on the upper end of a regular CV's operating range but workable.

from there i'll go to the transfer case's front output. with the beefy chain in an oil bath down to the clutch. from there I'll have a strait shaft between the t-case and the angry hamster box. there won't be any more side loading on the box's input shaft which should prevent the issues we saw before. but i'm still running all the power through it so i need to make sure i'll be alright there.

the lower shaft will spin up to 5200RPM I'll start with 1:1 gear in the angry box but i may tweak it a bit for drivability later. 1:1 is convenient since i already have them on hand.

the next step is to start dissembling this case, relocate the oil pickup and lop off the rear output to reduce the overall length.

Somehow I think this is a suboptimal solution, let alone a needlessly complex one.

You're going to be running power through 8 different assemblies, of which almost all will need to be custom-adapted, 3 of them will be changing drive ratio (first up, then down), and finally there are 3-4 points where you'd have to get major components aligned pretty damn well.

A keg against this particular design working and not blowing up in some spectacular fashion for the entire race.

Do you have a schematic of your engine bay that identifies basic dimensions and location of the engine, wheel hubs (when on the ground), and any points of interference? I really want to be more constructive and not just sit there and shoot down ideas, but I don't know the dimensions of what you're working with...

Any news?

Any news?

sure. our first child was born healthy last tuesday ![]()

so no, i don't really have an update at this point. but i still have a decent plan i think.

JdeMod wrote:Any news?

sure. our first child was born healthy last tuesday

so no, i don't really have an update at this point. but i still have a decent plan i think.

Congrats! Now, I'm pretty sure they have a Lemons onesie, and after that, there are always t-shirts. My 6 year old wears his with pride, as often as he can. Enjoy!

Congrats on the baby Marc! Hope you are all well and happy!

JdeMod wrote:Any news?

sure. our first child was born healthy last tuesday

so no, i don't really have an update at this point. but i still have a decent plan i think.

I would call that pretty significant news; probably the best in this thread thusfar.

congrats Marc....

Now you really have a complex piece of machinery to take care of.

Good luck.

Marc wrote:JdeMod wrote:Any news?

sure. our first child was born healthy last tuesday

so no, i don't really have an update at this point. but i still have a decent plan i think.

I would call that pretty significant news; probably the best in this thread thusfar.

I concur. Congratulations, Marc!

thanks guys, here is the little guy and his mom.

w00t! Congratulations!

well guys, I've got some very interesting results back from the guys that analysed my broken materials. (I don't want to name them in case they do not want to be named, but if they want to post who they are I'd be happy to let them plug their awesome services in my thread)

First thing is they did a chemical analysis on the shaft and the sprocket:

The shaft was as expected for a tough but not hardened shaft:

Cr 0.46

Ni 0.54

Mo 0.20

Cu 0.26

W 0.00

V 0.02

Mn 0.87

Fe 96.72

Ti 0.00

The gear on the other hand was very disappointing:

Cr 0.19

Ni 0.40

Mo 0.03

Cu 0.56

W 2.72

V 0.02

Mn 0.42

Fe 97.01

Ti 0.00

there are a few interesting points there. first thing is the manufacturer refers to this a ti-moly alloy. the titanium contents is undetectable if any at all. the moly contents is also very small. but in all fairness, from what i understand a little moly goes a very long way in an alloy.

the stuff machines like leaded chromoly alloy. I found this out because the piece wasn't entirely to size when i received it and i had to correct the bolt pattern.

but all that is sure with the above information is that the component i bought was mis-marketed. it was a motorcycle part that i was abusing. it may be fantastic for the original intended application.

here's the very interesting part, the fracture analysis indicated that the failure was mostly torsional rather than in bending.

the only torque on that part of the shaft is the drag from the end bearing. i haven't opened the angry hamster box yet, but I suspect the end bearing is completely failed/bound up. this is entirely not the failure that i expected, but the reason is probably the same. simply too much side load on the shaft destroyed the bearing which applied torque to the shaft.

the sum of all this means that the chain approach might be able to work, but at a minimum I'd need to place the chain in an oil bath with both ends mounted in double shear.

moving to an oil bath means i can use bigger industrial chains that require an oil bath and i can easily get a double sprocket and run two chains.

if i do this and support the whole lot on the transmission i can then use a short driveshaft between the engine and the top sprocket with rubber isolators or even a dual mass flywheel on the motor.

i could then put a lightweight flywheel in the Subaru box to reduce the back and forth pounding. the current is 27lbs and there are 9lb options available

the big reason I'm even reconsidering this is because of how far off the material was between what was promised and what was delivered. a sprocket of the proper material can probably handle this type of load just fine.

Off Topic:

Marc, you might want to download this now while it's still free. If you're not quite in need just yet, you will be. Trust me on this one. (link is embedded in the article)

http://latimesblogs.latimes.com/jacketc … sleep.html

Hope things are going great with the new family!

A quick way to check to see is a material is the right strength is a Rockwell hardness test. It's very cheap and easy and many fabrication shops will have one. If you can't find a hardness tester a scratch test could help. If you have something laying around that is about the hardness/strength you want, see if it will scratch the suspect part.

I Googled your Ti-moly alloy and it looks like is is supposed to be a steel. If so, I don't understand how the ads can claim it is 3X harder than stainless (some grades of stainless are hard, many are not) and yet 35% lighter than stainless steel. For that strength/density you'd have to be using a titanium alloy, not a steel with a dash of Ti in it. One post noted that it resists bending better than steel, and I don't believe that since other than for all practical purposes the stiffness of all steels are the same and on top of that stiffness is not related to strength or hardness. In fact, if they think they have a super hard material and so can used thinner stock, the part will be even easier to bend.

Can you ask your vendor what the standard alloy designation is? I'm beginning to think this is something fishy because I can only find the alloy mentioned on motorcycle sites and on eBay and other cheesy sites selling titanium steel jewelery, but not at any aerospace or metals sites.

Edit - I found a Chinese site that sells the material, but they listed it as a titanium alloy, and a legit casting site that finally did mention titanium steels as steels containing 0.5-2% titanium plus usually Ni, Cr, and other elements.

A quick way to check to see is a material is the right strength is a Rockwell hardness test. It's very cheap and easy and many fabrication shops will have one. If you can't find a hardness tester a scratch test could help. If you have something laying around that is about the hardness/strength you want, see if it will scratch the suspect part.

I Googled your Ti-moly alloy and it looks like is is supposed to be a steel. If so, I don't understand how the ads can claim it is 3X harder than stainless (some grades of stainless are hard, many are not) and yet 35% lighter than stainless steel. For that strength/density you'd have to be using a titanium alloy, not a steel with a dash of Ti in it. One post noted that it resists bending better than steel, and I don't believe that since other than for all practical purposes the stiffness of all steels are the same and on top of that stiffness is not related to strength or hardness. In fact, if they think they have a super hard material and so can used thinner stock, the part will be even easier to bend.

Can you ask your vendor what the standard alloy designation is? I'm beginning to think this is something fishy because I can only find the alloy mentioned on motorcycle sites and on eBay and other cheesy sites selling titanium steel jewelery, but not at any aerospace or metals sites.

Edit - I found a Chinese site that sells the material, but they listed it as a titanium alloy, and a legit casting site that finally did mention titanium steels as steels containing 0.5-2% titanium plus usually Ni, Cr, and other elements.

sorry, i did not see this earlier. but i find it difficult to expend more energy on that sprocket nightmare. i'm joinst going to move on and the sprocket is hung in the garage as a reminder to do my homework first.

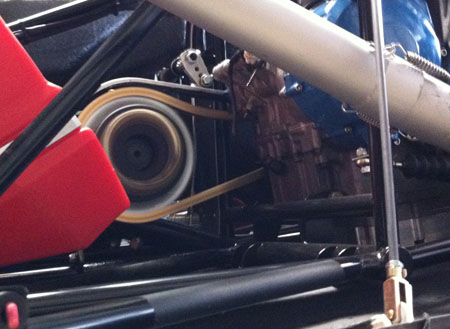

but anyways, i ran across something interesting a few days ago. i follow this guy's site: http://dpcars.net/ he builds really neat stuff. but a few days ago he posted the two following pictures:

(from this post: http://dpcars.net/dp4/recent.htm)

anyways, he's being pretty secretive about it, but the car is on a dyno and it's obvious that one picture is under accel and the other is under coast.

if you do a few educated estimates, that sprocket is probably spinning around 1800RPMs in that picture. and the sprocket is about 9" in outer diameter. these aren't facts, these are estimates based on info over the many builds he's done. if someone knows better info do tell.

but the important number there is that chain is moving at approximately 45-55mph surface speed and it's really deforming itself.

if you take my slightly over 11" sprocket at 1900RPM my chain was moving at about 65mph surface speed.

suddenly i have a lot more appreciation for the forces at play in my setup. if i do have any kind of chain in the system, i definitely need to keep the upper sprocket a bit smaller than my previous setup to keep the chain surface speed a bit lower.

Great to see an update!

Hope the baby is doing well! Post pics.

The 24 Hours of Lemons Forums → The Airplane-Powered MR2 → Never before has so little power been made from so much displacement!