I actually *DO* have an update, I was in the shop working on it today.

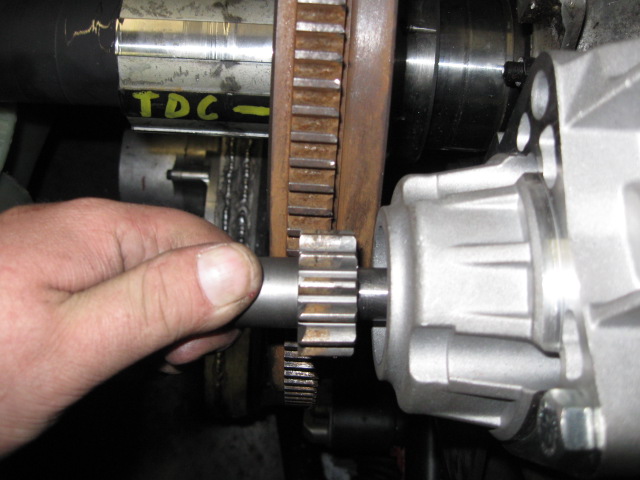

I removed the old snout/chain drive assembly and reused it's flange for the flywheel mount

Then i machined the rear of the flywheel slightly to add a locating pilot and the proper bolt pattern:

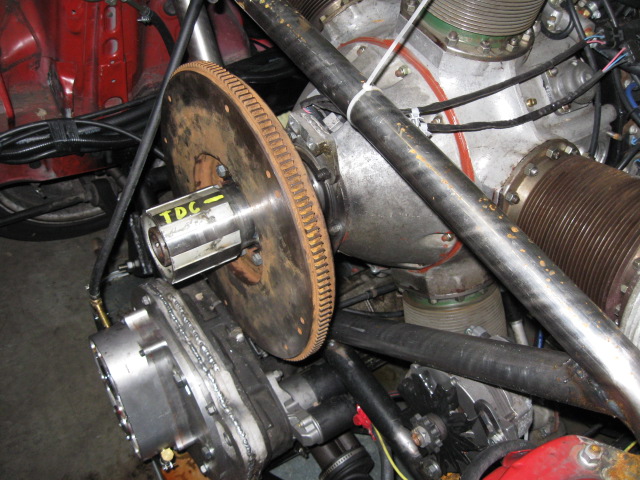

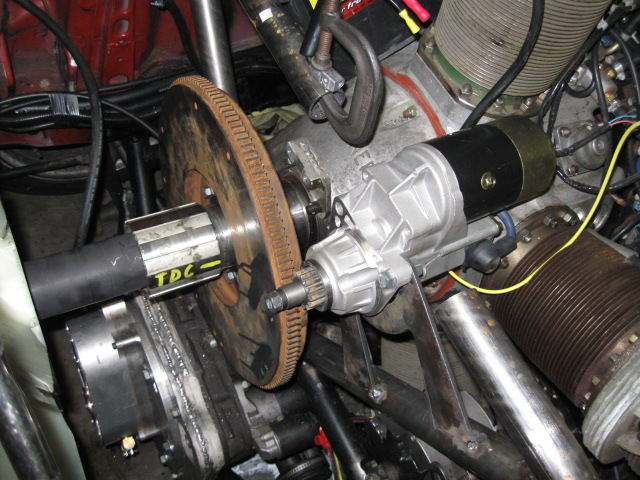

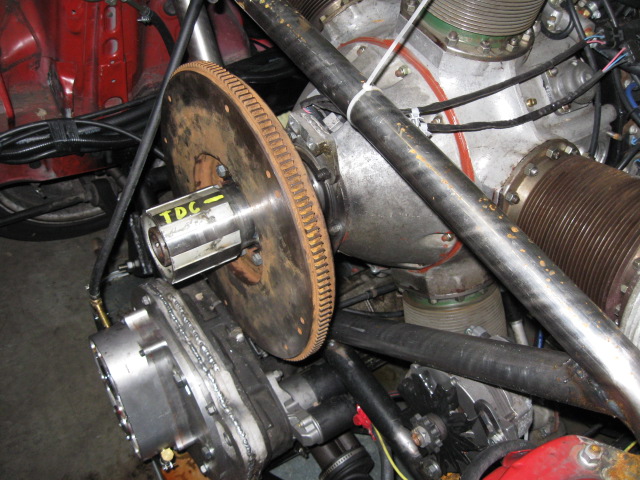

then the whole thing fits!

about an inch of clearance to the transmission.

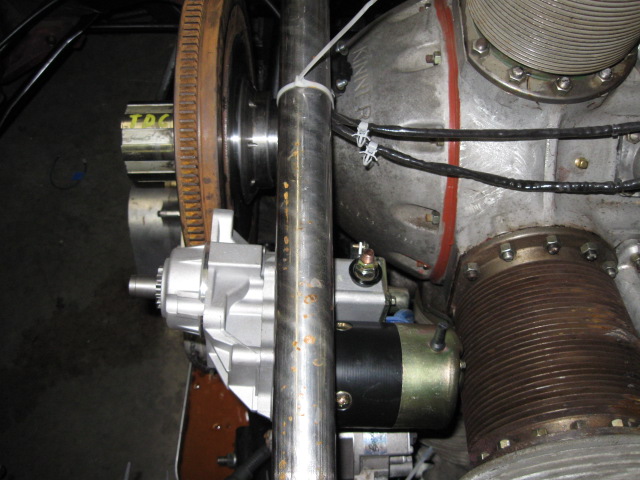

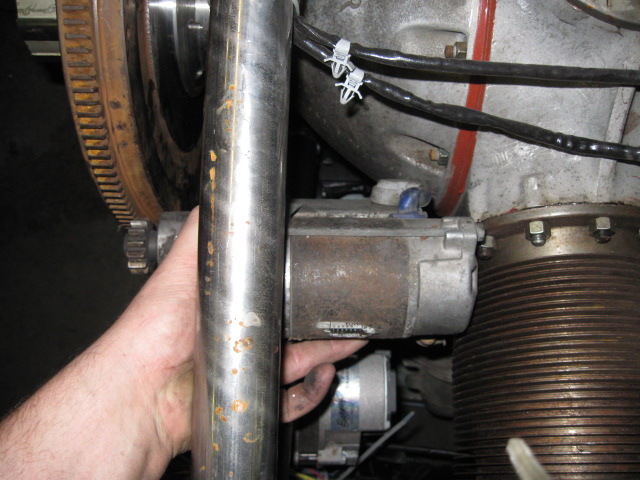

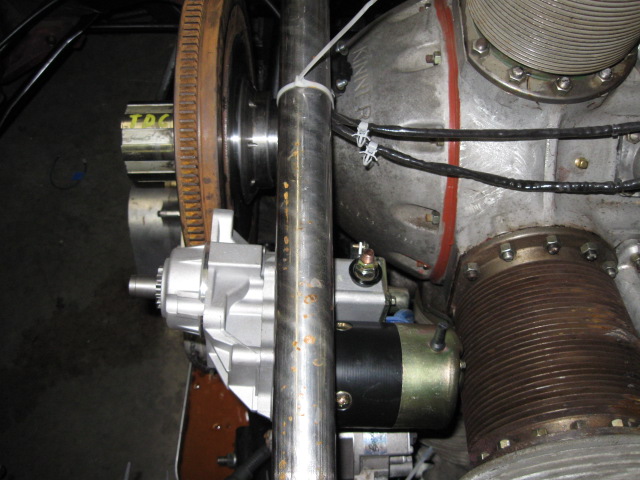

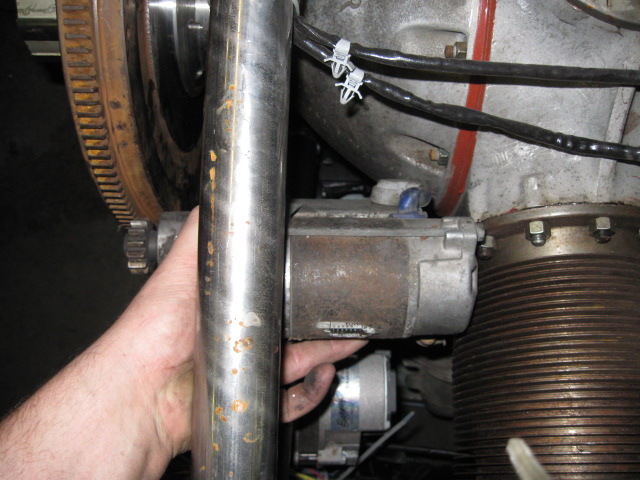

of course, tomorrow's work looks a bit more complicated, the strut bar i welded in to make up for the removed firewall is in the way of the starter:

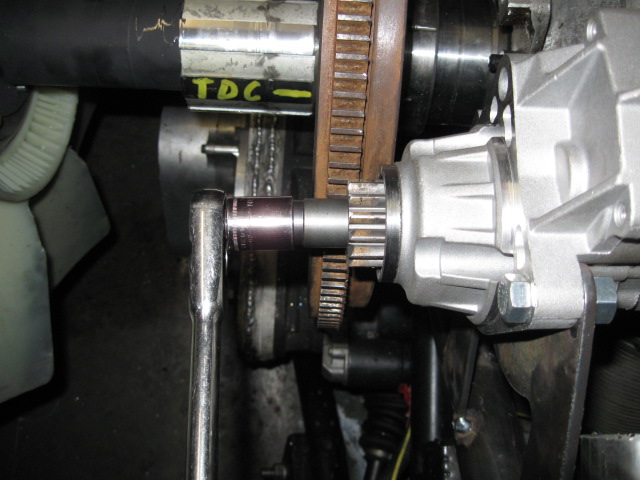

i just need to go a bit higher to make the starter not interfere with the number 5 cylinder.

alternately, i could use a smaller starter and not modify the strut bar:

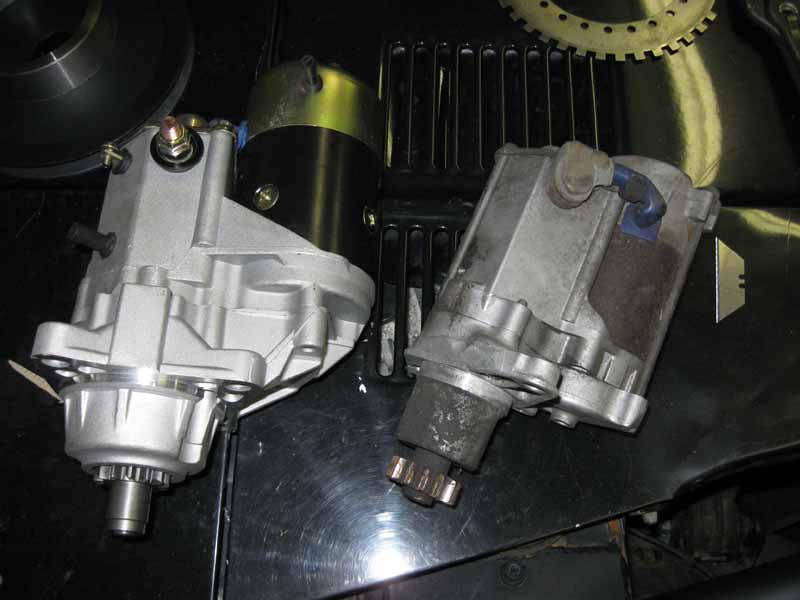

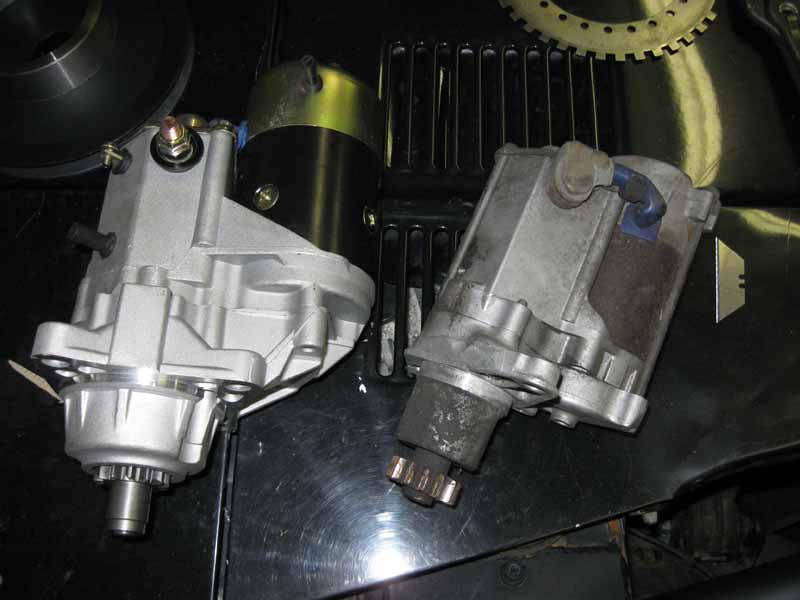

here's a shot of the two starters. the one on the left is a cummins turbo diesel starter and the one on the right is a 2nd gen turbo MR2 starter it spins the wrong way, but there are others available in that form factor.

but i think it would be a bad idea to go with the smaller one since that's equivalent horsepower to the previous starter i used and even with the 3:1 torque increase going through the chain drive it was barely able to spin the motor 25-30RPMs. it's possible there was just that much friction in the entire system and it would be fine directly mounted there.

it also seems that as i'm running the motor, the rings are taking a good seat and sealling better and better. overall, this is good but it does add quite a bit of effort required from the starter. i can't turn over the engine by hand anymore, i need a 4ft pry bar now.