Re: Never before has so little power been made from so much displacement!

Hopefully you'll get to this point. Totally awesome project!

http://www.youtube.com/watch?v=luvkcP0m … re=related

The 24 Hours of Lemons Forums → The Airplane-Powered MR2 → Never before has so little power been made from so much displacement!

Hopefully you'll get to this point. Totally awesome project!

http://www.youtube.com/watch?v=luvkcP0m … re=related

Hopefully you'll get to this point. Totally awesome project!

A dragstrip run is planned. but I'm expecting something more like 16-18seconds down the 1/4 mile. that german car is much lighter and the motor is much larger.

thanks for the video, it's fantastic ![]() i like how the launch sounds like he's just launching at idle.

i like how the launch sounds like he's just launching at idle.

Well, I did a bunch of math today and realized I have a significant issue that I should have noticed earlier.

That secondary driveshaft between the transfer case and the transmission will be spinning very fast. This was known a while back. Unfortunately I had forgotten that the faster you spin a driveshaft the lower the operating angle is (using CV joints or u-joints, it does not matter).

At 6000RPMs I should not have more than about 4degrees of angle which places the transfer case about 3ft inside the car… damnit.

New plan is to make a much more vertical transfer case. I need to cover a distance of 16”, reverse the rotation direction and increase the RPMs by 3:1 at a minimum.

My current thought is a beefy chain at the top (so it moves slower) and a set of quick change gears at the transmission input. I just need to figure out if I can run that chain exposed to the elements or if it needs to be submerged in an oil bath. If someone knows how to work those numbers I’d appreciate it. (figure 600lb*ft of torque, sprocket sizes: 5.9” and 2.9”, chain speed max: 51ft/sec 35mph)

Seems that the above falls well within the usage of a standard motorcycle chain but I don’t know if it will be happy about doing it at a much higher duty cycle. Obviously a motorcycle can only put down 600lb*ft to the final drive chain for a limited amount of time before the driver becomes an organ donor. In that sense it’s somewhat of a self limiting system.

How about the big chains used in the drive systems of the V8 Toronados and Eldorados? I'm sure they're hell to pull out of a junked car, but you should be able to find plenty of late-70s Eldo donor cars.

Marc, why not just use a big gates belt, ala PSRU?

http://www.mcmaster.com/#roller-chain/=axn9p0

Take chain load rating in pounds, then divide it by output (engine-side) sprocket radius in fractions of a foot, and see if it's more than 600. If it is, the chain will work. If not, get a bigger sprocket or a stronger chain.

Mount the sprocket on the engine, maybe with an extension shaft (to put the engine behind the transmission). Then assemble a light flywheel, a clutch, and a 2x-3x smaller sprocket together and attach said assembly to the transmission. Connect the two together with a chain, with the engine sitting behind and somewhat on top of the transmission, and then rigidly couple the engine with its transmission. That's how I'd do it.

I think Saab uses a very similar system, and so did TH425, as Murilee mentioned (although TH was automatic only, and Saab had manual gearboxes).

mostly because I can't seem to find any information at all on those belts. do you have a link to a catalog?

I did just talk to a high end bike chain manufacturer and he seems reasonably comfortable with the application. he said he could make some oversize sprockets to reduce the amount of tension on the chain.

but if you can help me find information on those prop speed reduction belts (and pulleys) then that might be a significantly cheaper option.

both of the above solutions would be great since i can run them "dry"

as for the tornado belt, they don't meet the ratio i need.

That engine would be happier as a constant speed unit, so why not build a hybrid? Hook the radial up to a generator and use an electric motor for propulsion. Risk of dramatic engine failure AND electrocution!!!

On your 550 degree temp number, if I see cylinder head temps heading past 400 degrees, I am pretty sure that I have a serious problem.

That engine would be happier as a constant speed unit, so why not build a hybrid? Hook the radial up to a generator and use an electric motor for propulsion. Risk of dramatic engine failure AND electrocution!!!

On your 550 degree temp number, if I see cylinder head temps heading past 400 degrees, I am pretty sure that I have a serious problem.

i agree that the temp seems rather high. but i was able to find a book on this engine that gives me all sorts of operating conditions like oil in/out temp, consumption, max cylinder temp and max head temp as well as a slew of others. plus, since i'm not counting on this engine to keep me in the air, i'll go ahead and trust it until it goes above or makes a funny noise.

i think that the constant speed nature of this motor us due to the original carburetor setup. i think that with the 5 individual carburetors it will not mind changing speeds at the driver's whim. we'll see.

mostly because I can't seem to find any information at all on those belts. do you have a link to a catalog?

I did just talk to a high end bike chain manufacturer and he seems reasonably comfortable with the application. he said he could make some oversize sprockets to reduce the amount of tension on the chain.

but if you can help me find information on those prop speed reduction belts (and pulleys) then that might be a significantly cheaper option.

both of the above solutions would be great since i can run them "dry"

as for the tornado belt, they don't meet the ratio i need.

Just googly it.. Some of the ones I found have a mind numbing amount of calcs to them, but call any belt supplier and tell them how much RPM, torque and pulley size you want and they will tell you how much belt... need about a 4" belt for this prolly. I've just been doing this as I am converting my 12x37 lathe to CNC with timing belts....

here's a quick google, but the gates people or distributors can size it right for you

http://www.durabelt.com/instructionsbeltsizer.php

http://www.gates.com/index.cfm?location_id=560

well, i did finally find the right guide: http://www.gates.com/catalogs/file_disp … s\catalogs

what was hampering my search efforts is i thought they were called cogged belts. searching for "poly chain"yields much better results.

it guides you through all the calculations. they are certainly lengthy but explained very well.

after following the guide, the power is too high for the desired RPM. if i fudge the numbers a bunch (about 1/2 the rated power and decrease the RPMs by about 20% i can get a belt. but it's a $570 belt. the sprockets aren't cheap either.

at that price, I can use a double row chain that is much beefier.

obviously I've got some more thinking to do on this.

but that aside, progress continues, a buddy came over and we completely stripped the car's interior. it's amazing how much weight the interior of a car weighs. nothing really picture worthy.

heh. with that much torque you could have left the interior in. or pull it out and replace the interior with solid gold ingots...yeah, that would be sweeeeet.

oh, the missing part to the equation i was initially calculating is that if i move more of the RPM multiplication mostly into the quick change gears i suddenly find myself into a designable region on those polychain belts.

(note, prices aren't shopped around a bunch, i just found one quick online supplier. more research needed here)

this belt: 1190-14MGT-85 ($218)

this sprocket: P30-14MGT-85 ($180)

and this sprocket: P44-14MGT-85 ($246)

total: $644

and while the solution may not be perfect, it's likely going to last longer than the chain setup. at the very least, it won't be as dangerous when it gets thrown clear of the car.

Well, I did a bunch of math today and realized I have a significant issue that I should have noticed earlier.

That secondary driveshaft between the transfer case and the transmission will be spinning very fast. This was known a while back. Unfortunately I had forgotten that the faster you spin a driveshaft the lower the operating angle is (using CV joints or u-joints, it does not matter).

At 6000RPMs I should not have more than about 4degrees of angle which places the transfer case about 3ft inside the car… damnit.

New plan is to make a much more vertical transfer case. I need to cover a distance of 16”, reverse the rotation direction and increase the RPMs by 3:1 at a minimum.

Ooooh, far more Lemons experience with this than I want to admit. First there is a big difference in what the different style of CV joints can handle. A rezeppa style where the ball cage is sliding can barely handle 1deg at 6K, a tripod style CV can handle the 4deg you mentioned as long as you have good grease in it, but a double-cardan CV can handle out to 7deg at that speed because the only sliding contact is the spherical phasing joint in the center of it. Take a look at Spicer 1310 CV's (aka Ford Ranger front driveshaft) if you can handle the longer length.

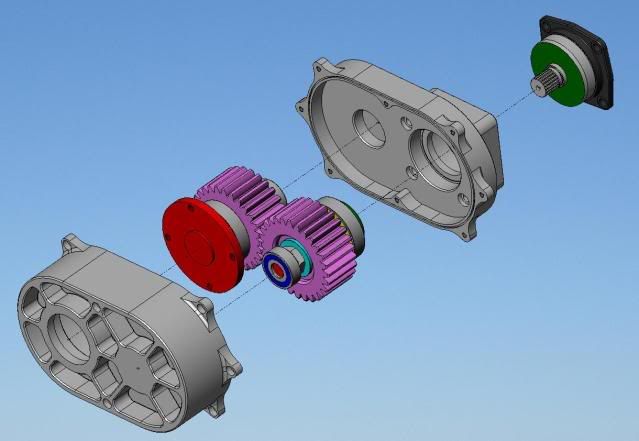

If you need a quick change gearbox the one I made for the previous incarnation of the Angry Hamster is up for adoption...I can't remember if I left enough room in the case to fit 3:1 gears though.

My current thought is a beefy chain at the top (so it moves slower) and a set of quick change gears at the transmission input. I just need to figure out if I can run that chain exposed to the elements or if it needs to be submerged in an oil bath. If someone knows how to work those numbers I’d appreciate it. (figure 600lb*ft of torque, sprocket sizes: 5.9” and 2.9”, chain speed max: 51ft/sec 35mph)

Seems that the above falls well within the usage of a standard motorcycle chain but I don’t know if it will be happy about doing it at a much higher duty cycle. Obviously a motorcycle can only put down 600lb*ft to the final drive chain for a limited amount of time before the driver becomes an organ donor. In that sense it’s somewhat of a self limiting system.

As long as you have a bike chain running in even the slightest oil bath you will not have any problems. All of the commercial chain life calculators are incredibly conservative and will have you spec. chain that weighs more than your car if you add in all of their load multipliers. Heat is what kills drive chains in bike engined cars because you can actually put down all the power. So you need to have an oil bath and keep the sprocket diameters as large as reasonable to minimize the flexing of the chain.

OH! what are you looking to get out of that box? are you willing to part with the drawings so I can make precise modifications to it?

is it a 6 spline or a 10 spline? I only need to fit 2.1:1 gears in it which are about 4.25" in OD on the big gear.

Just pay the shipping costs and it's yours. I don't even want to think about how much labor I have into it. Yes, I'll give you any drawings you need and it's set up for 10 spline gears right now. When I checked the model you can fit a 4.25" gear in there but you will need to modify the vent system because it's going to act like a positive displacement pump sending oil everywhere when the gear gets that close to the case.

-Tim

Just pay the shipping costs and it's yours. I don't even want to think about how much labor I have into it. Yes, I'll give you any drawings you need and it's set up for 10 spline gears right now. When I checked the model you can fit a 4.25" gear in there but you will need to modify the vent system because it's going to act like a positive displacement pump sending oil everywhere when the gear gets that close to the case.

-Tim

You rock!. I'm sending you an e-mail with the shipping info.

Marc, I woke up at 4am this morning thinking about your project. I get the publication from the Aviation Engine Historical Society http://www.enginehistory.org/ and remembered an article on the power pulses and how the flywheel effect of the propeller was necessary for the engine to run properly. So I called a company I know that rebuilds radial engines and they also suggested that even with the load of the drivetrain that engine is going to be happiest with a flywheel or clutch arrangement of some sort attached to the crankshaft similar to what they did with WWII radial powered land vehicles, the M4 Sherman tank http://en.wikipedia.org/wiki/M4_Sherman and the tracked landing vehicles. http://en.wikipedia.org/wiki/Landing_Vehicle_Tracked Pretty cool fan and duct setup

http://www.youtube.com/watch?v=m6tL69gHybk

I subscribe to this magazine and they have a good search engine http://www.enginehistory.org/

yup, the propellers provide quite a bit of rotational inertia, but i think i have enough as it is. keep in mind that i'm using a normal automotive clutch with a stock subaru flywheel (almost 20lbs) the flywheel is spinning at 3x the engine speed which should help it store much more energy than it's size would otherwise dictate. plus there's all the shafts and gears inbetween. it should be pretty close to what the prop would provide.

i could definitely use one of those fans. know where i can buy one?

This is why Squirrelly Z600 is a Legend of Lemons!

Also, please don't make some kind of sketchy-ass flywheel out of manhole covers, tires full of concrete, etc.

Just pay the shipping costs and it's yours. I don't even want to think about how much labor I have into it. Yes, I'll give you any drawings you need and it's set up for 10 spline gears right now. When I checked the model you can fit a 4.25" gear in there but you will need to modify the vent system because it's going to act like a positive displacement pump sending oil everywhere when the gear gets that close to the case.

-Tim

Tim, this is pretty awesome of you to do. If you ever end up in the midwest, let me know, would love to buy you a beer.

It's worth mentioning that it's this kind of stuff that separates Lemons from the rest of the entire freaking automotive world. It's awesome when "crackpots unite" is a rallying cry.

Also, please don't make some kind of sketchy-ass flywheel out of manhole covers

Dammit. Back to the drawing board.

It's worth mentioning that it's this kind of stuff that separates Lemons from the rest of the entire freaking automotive world. It's awesome when "crackpots unite" is a rallying cry.

Credit where credit is due. Phil is the one who taught me that when someone is this far "down the rabbit hole" the only fair thing to do is toss in another carrot and kick dirt over the exit. It makes for maximum entertainment that way ![]()

If we ever do Lemons Russia, jet engines will be mandatory!

The 24 Hours of Lemons Forums → The Airplane-Powered MR2 → Never before has so little power been made from so much displacement!